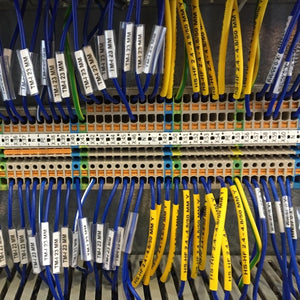

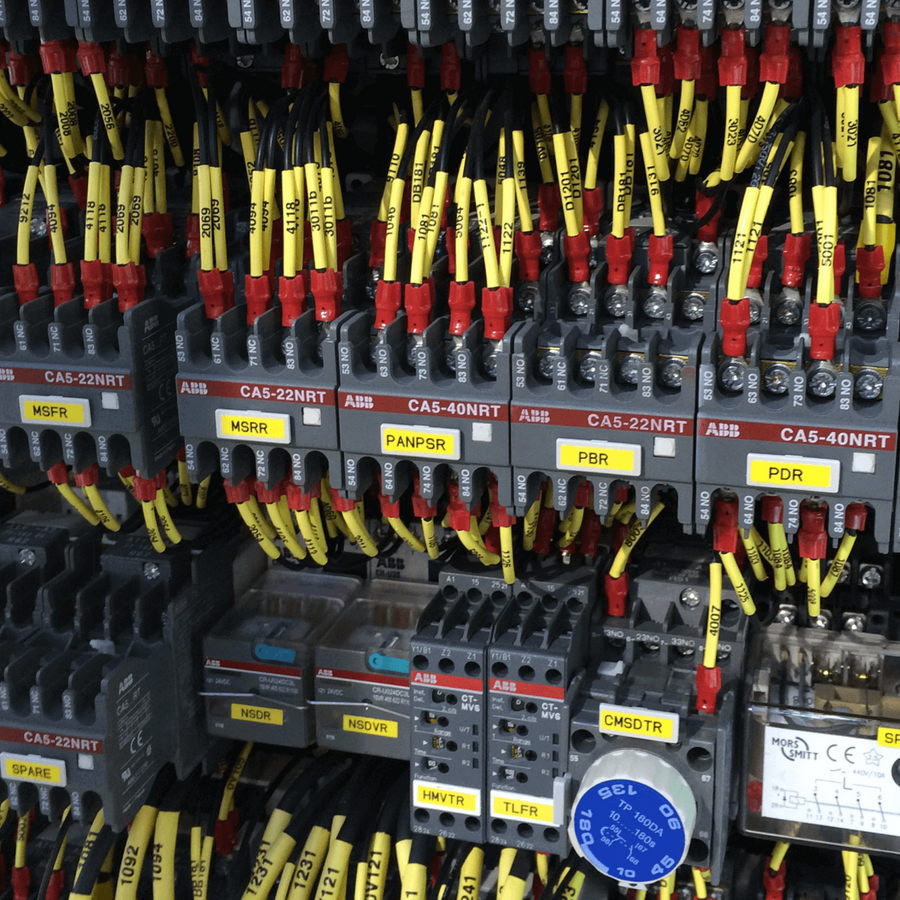

In industrial applications, standard-compliant electrical labeling of conductors and cables is a central component of electrical installation technology. Clear and permanently legible labelling of cables enables electricians to quickly assign circuits, efficiently locate sources of faults and carry out maintenance work safely and quickly. In addition, standard-compliant labeling makes a significant contribution to operational safety and is also required by law in many cases.

Below we present the most common methods for labeling electrical cables. These methods are also suitable for standard-compliant cable marking of electrical cables in accordance with DIN EN 60445 and for marking electrical equipment in machinery in accordance with DIN EN 60204-1.

Cable labeling options for electrical installations

There are numerous solutions available in the industry for marking wires and electrical cables. Different marking methods are used depending on the sector, installation situation and requirements. Printable cable markers in particular have proven their worth: They are robust, durable and offer great time savings thanks to easy handling.

Our range includes versatile solutions that differ in terms of mounting method (e.g. clip-on, wrapping) and material. This allows cable marking to be specifically adapted to different applications - for example for marking in control cabinet construction, mechanical engineering or plant construction. In the following overview, we show you the most common methods with their advantages and typical results in industrial use.

Heat shrink markers for electrical cables

So-called shrink sleeve markers (or marking sleeves) are ideal for the permanently legible labeling of electrical cables. Whether in control cabinets, on electrical cables in PV systems or in cable assembly: printable shrink sleeves can be used universally and score particularly well in terms of their robustness and resistance to UV rays, high temperatures and chemicals. The markers are usually made of polyolefins, can be used for various cable diameters and can be permanently labeled with the appropriate thermal transfer printer. The tubes are pushed onto the corresponding cables and shrunk to fit the cable precisely by applying heat at certain points. This means that the cable is not only marked, but also protected against mechanical damage. These cable markers are also suitable for conductors or for marking cables with small diameters.

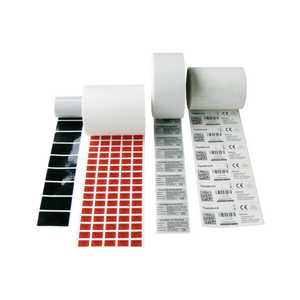

Cable labels for electrical engineering

Another very popular method for marking electrical cables is the use of cable labels, known as wrap-around labels. These labels, which are on a roll, can also be permanently labeled using a thermal transfer printer. In the case of self-laminating cable labels, the label field is specially protected from environmental influences by a protective laminate. One advantage of labeling electrical cables using labels is that they are self-adhesive and can also be used on cables that have already been installed. They are therefore also suitable for the subsequent marking of electrical cables. They are particularly suitable for labeling electrical systems and also comply with the current DIN standards for cable marking in control cabinets. The areas of application for use in electrical engineering are correspondingly broad.

Cable labels for electrical installations

The use of cable labels has also proved very successful for industrial cable marking. Cable labels are attached to the corresponding electrical cables using cable ties. These markers are usually made of high-quality plastic (e.g. polyester, PVC or polyurethane) and can either be labeled manually or printed using a printer. This type of cable marker is available in different colors and is often used in control cabinet construction, but is also regularly used for marking systems, machines, components and electrical devices. One advantage of cable labels is that the labeling field is not directly dependent on the cable diameter. Cable labels are also suitable for labeling cables.

Cable labeling Electrical installation

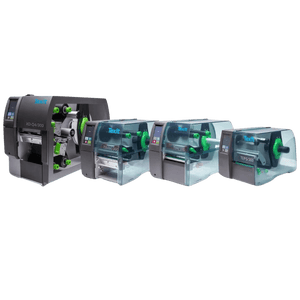

No matter which option you ultimately choose: When it comes to printing markers, it always comes down to the right printing system. Depending on the materials used and the requirements on site, we at Texit will put together the optimum printing system for you. We always provide you with a customized solution that is precisely tailored to your requirements and wishes. This makes cable marking of electrical installations flexible and easy!

The first step is to work with you to select the right items or cable markers. Which of our products is most suitable for you depends primarily on the situation on site. We select the right product depending on the cable diameter, environmental influences on site and individual or legal standards. In the next step, the choice of printing system depends on this selection: we adapt thermal transfer printers, ribbons and label software to your requirements. This allows you to benefit from maximum flexibility in cable marking in the long term.

If you only need cable marking products for selected projects, we also offer a printing service or the rental of our thermal transfer printers. Simply contact our service department and save yourself a large investment.

Do you need support with electrical cable labeling? We will be happy to advise you!

FAQ Labeling electrical cables

How do you label electrical cables?

How do you label electrical cables?

Electrical cables are labeled in electrical engineering and construction to improve identification and avoid faults. The marking can vary depending on the application and standards. Standards such as VDE, DIN and IEC specify how electrical cables must be labeled depending on the area of application in order to make installation and maintenance safe and efficient. In industry, electrical cables are usually marked with permanently legible shrink sleeves, cable labels (with or without cable ties) or cable labels.

Why label cables for electrical installations?

Why label cables for electrical installations?

The labeling or marking of electrical cables and lines is particularly important to prevent confusion and cable clutter during maintenance and repair work, thereby increasing safety. For this reason, the legibility of cable markings should also be permanent (>10 years). Cable marking includes the marking of cables, cores, conductors and wires as well as the marking of similar electrotechnical components such as sleeves, fabrics, connections and the labeling of systems. There is a wide range of types and designs available: From cable markers to shrink sleeves and labels. At Texit, we have specialized in precisely this diverse field: The professional and DIN standard-compliant labeling of cables in industry.

Which standards must be complied with for electrical cable labeling?

Which standards must be complied with for electrical cable labeling?

In the industrial and commercial sector, the applicable DIN standards for electrical cable labeling must be complied with. The most important standards for electrical installation cable labeling in Germany are the following standards:

DIN EN 60445 Specifies the basic rules for the color and alphanumeric marking of conductor ends.

Example: Protective conductor = green-yellow, neutral conductor = blue, outer conductor = brown/black/grey.

DIN EN 60204-1 regulates the electrical equipment of machines. Requires, among other things, clear and permanent conductor identification - including cable colors, numbering or labels.

DIN EN 61439 Applies to low-voltage switchgear and controlgear assemblies (e.g. control cabinets). Standard-compliant labeling of all equipment and conductors is required here.

DGUV regulation 3 (= accident prevention regulation "Electrical systems and equipment")

Requires proper labeling to avoid electrical hazards.

In practice, this means that cables and conductors must always be clearly identifiable, for example by means of clear color coding, numbering or corresponding labels. At Texit, we have specialized our range of marking products to meet precisely these requirements. If you have any further questions, our marking experts will be happy to advise you personally on your specific requirements.

Why should cables and conductors in electrical engineering be labeled?

Why should cables and conductors in electrical engineering be labeled?

The labeling or marking of electrical cables and lines is particularly important to prevent confusion during maintenance and repair work. Therefore, the legibility of the cable markings should also be permanent (>10 years). Cable marking includes the marking of cables, cores, conductors and wires as well as the marking of similar electrotechnical components such as sleeves, fabrics, connections and the labeling of systems. There is a wide range of types and designs available: From cable markers to shrink sleeves and labels. At Texit, we have specialized in precisely this diverse field: Professional and DIN standard-compliant marking in industry.

What is part of electrical labeling?

What is part of electrical labeling?

Electrical marking includes various elements that are necessary for the safe and standard-compliant marking of electrical systems and equipment. In our online store you will find a wide range of products, from warning signs and electrical symbols to special markings for switch boxes, plugs and mains plugs. These markings provide information about relevant hazards, such as voltage and current, and are particularly important for systems with high voltage. Typical symbols such as the lightning bolt or the arc illustrate the electrical hazard and help to prevent accidents. You can add the appropriate markings directly to the shopping cart and request them using the filter. All in all, electrical labeling makes a significant contribution to making hazards visible and ensuring the safe handling of electrical components.