Enclosure labeling: Space-saving, flexibly adaptable & permanently legible

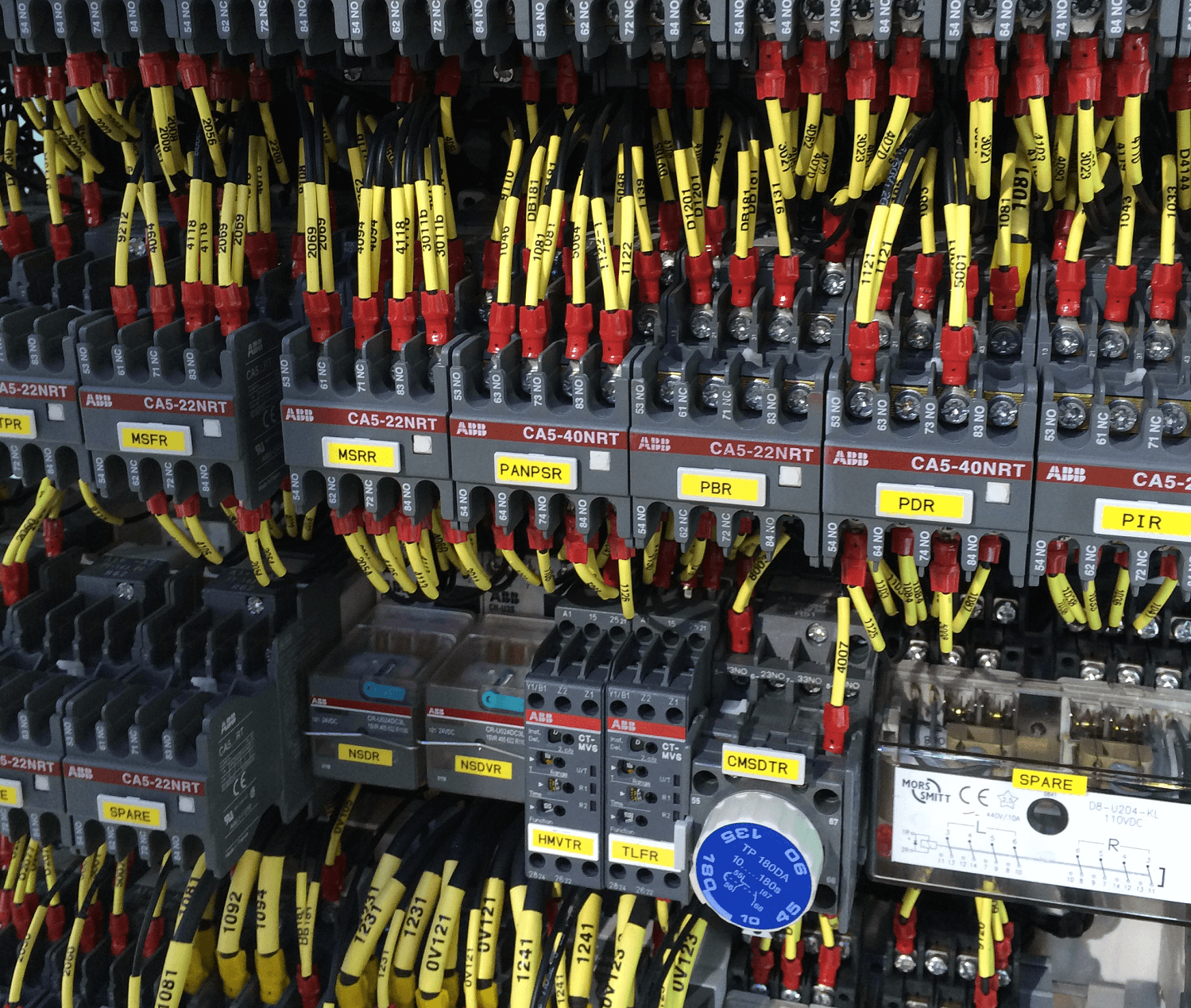

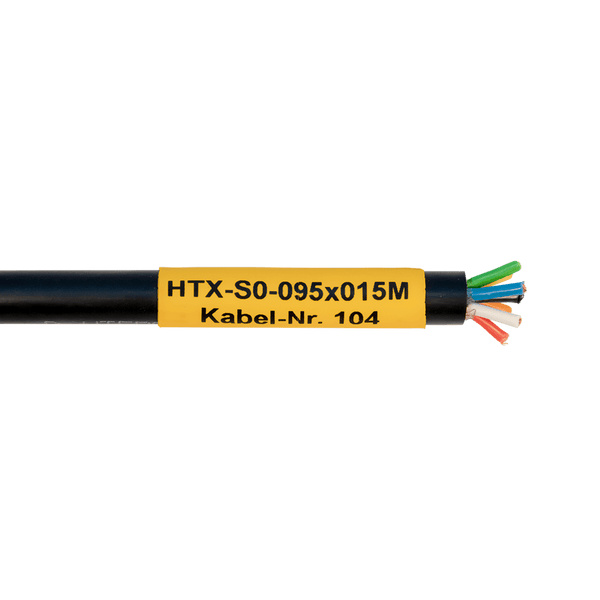

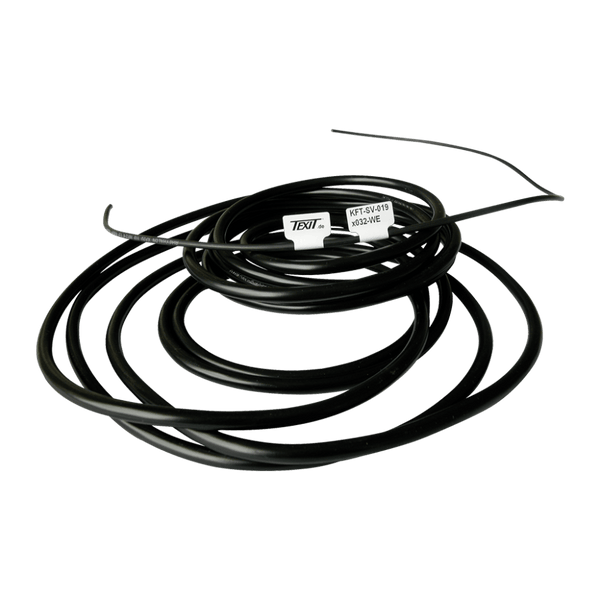

The certified Texit quality of the print ensures permanent legibility (>10 years) and guarantees a smooth process during frequent conversion, modernization and maintenance measures. Even after several years, all individual wires and cables in the switch cabinet remain clearly identifiable and faults can be rectified quickly.

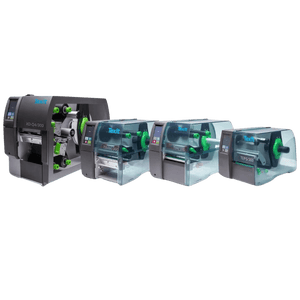

You can import all the required data for the electrotechnical automation processes using our label software, simply drag and drop the components (text, code, barcode) onto the label plates and arrange them individually. In addition to high-quality control cabinet labels and cable markers, we can also offer you labeling strips using a laser printer or manual labeling by hand. In practice, however, the identification of devices and documentation using thermal transfer labeling has become established among leading experts in switch cabinet construction.

✔️ Flexible control cabinet labeling (grommets, signs, cable markings) that can be printed with just one printing system (high compatibility)

✔️ CE marking with flexible fabric markers and nameplate labels in and on control cabinets

✔️ Savings in time & costs thanks to the long service life (high level of safety in the event of subsequent changes to the design & maintenance measures of the control cabinets)

✔️ Efficient troubleshooting through easy identification of individual cables, lines, and equipment

✔️ Time & cost savings for subsequent maintenance / repair & replacement work.

✔️ Very easy to use and mount in control cabinets

✔️ Large selection of space-saving products with long service life

✔️ Benefit from our Texit service & technical support in the long term

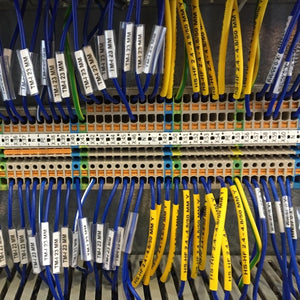

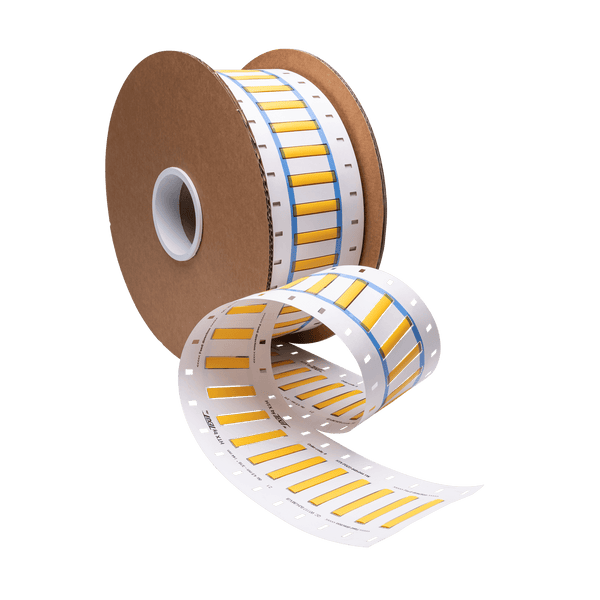

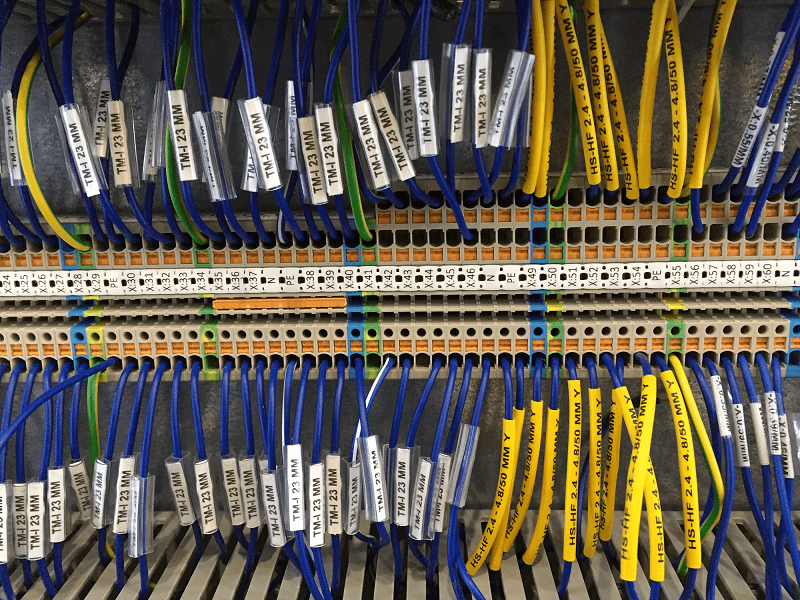

Enclosure labeling grommets

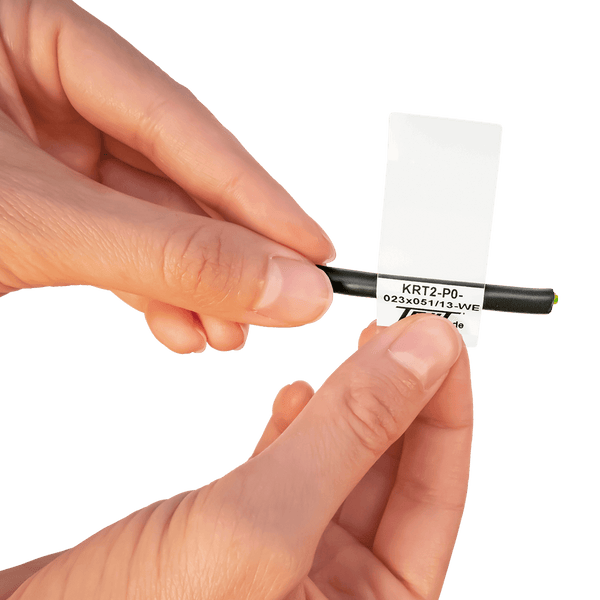

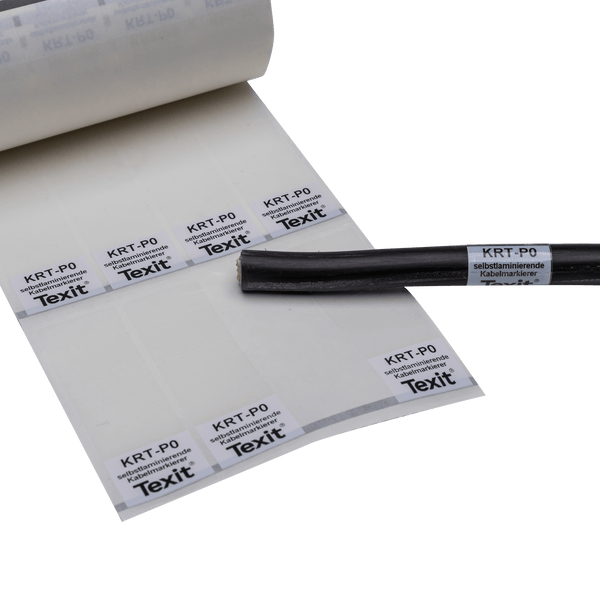

Labeling grommets, so-called shrink sleeve markers, are used very frequently in switch cabinet construction. They are particularly suitable for marking individual wires and electrical cables in control cabinets. Thanks to the high-quality polyolefins, these markers can easily withstand heavy loads in control cabinets and meet all current standards and requirements of control cabinet manufacturers. As a manufacturing company and manufacturer of markings, we can also offer you custom-made products that meet the requirements of your machines and systems (e.g. in terms of color, size or manufacturer's guidelines).

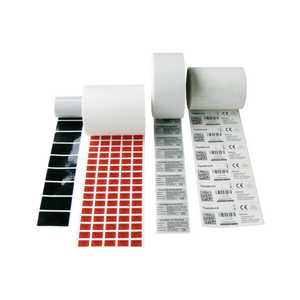

Switch cabinet labeling Labels

Especially in control cabinets, the space for labeling is very limited and there are many corners and edges. The Texit fabric labels meet even these difficult requirements of control cabinet builders. The labels are made of ultra conformable textile fabric and are already provided with permanently adhesive acrylate glue. As a result, they adhere permanently even to uneven surfaces, corners and edges and withstand high loads in the machine without any problems. In practice, these labels have already proven themselves many times over as part of the systems for labeling.

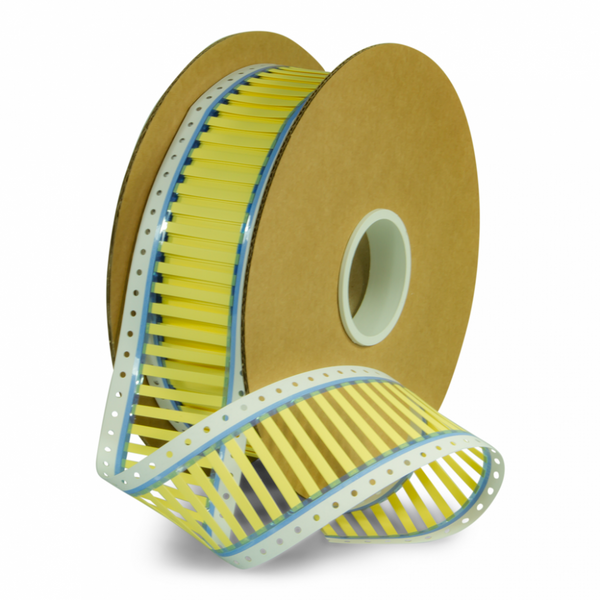

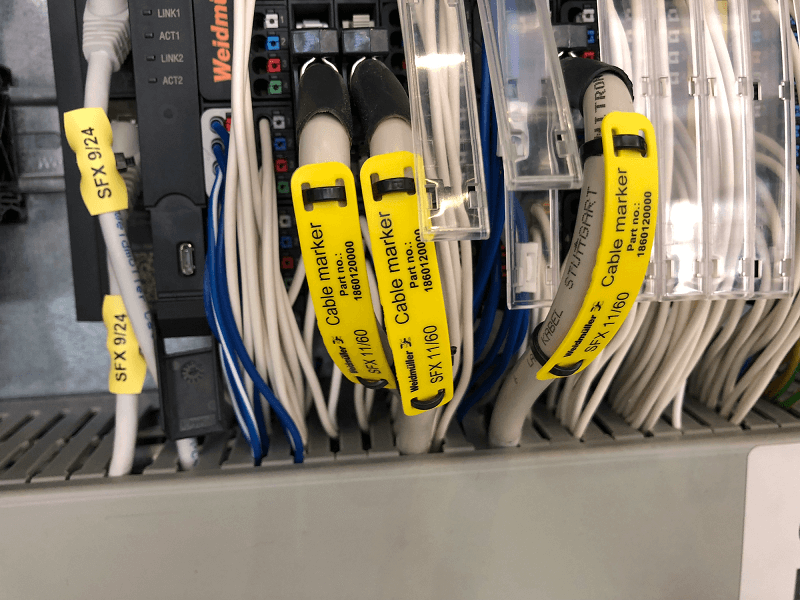

Clips and terminals switch cabinet

The push-on cable marker makes an important contribution to safety in switch cabinet construction and subsequent control. The flexible application and easy handling of ART wire markers, together with their permanent legibility, contribute to compliance with the standard and directive for labeling in the control cabinet. The markers can be printed flexibly and easily using the thermal transfer printing system and can be attached to the individual wires of an electrical enclosure without any tools. They meet the current requirements and standards in enclosure construction and can also be easily adapted in the event of changes thanks to rapid development.

Switch cabinet labeling Safety

Just as for other equipment (systems, machines, ...), the use of warning signs is also part of the safety labeling when planning and developing control cabinets. Companies in the manufacturing sector must ensure safety in the control and planning of production. In this sense, warning signs play an important role in control cabinet construction as an image of potential hazards. Texit's warning signs are available in different shapes and sizes and can be printed flexibly as required using the thermal transfer printing system.

For flexible & cheap CE marking

Nameplate labels

As a control panel manufacturer, each piece of equipment must be labeled with the typical manufacturer's information. Our nameplate labels are an excellent, cost-effective alternative to conventional engraved metal nameplates. They can also be used outside of control cabinets on machinery and equipment. Our Texit nameplates can also be easily printed with the thermal transfer system and meet the current standards and guidelines for documenting the manufacture of control cabinets and machines.

Looking for even more labeling for the control cabinet?

Discover our full range of control cabinet labeling.

Marking made easy in the control cabinet

Enclosure labeling can be quick, easy and uncomplicated. At Texit, we guarantee our customers a special service in addition to excellent product quality. You will be assigned a trained expert as a permanent contact who will advise you on the right products and will also look after you afterwards, solving problems and optimizing the use of our products on site at your premises.

As an ISO-certified company, you can rely on our 20 years of experience in the field of industrial labelling.

Would you like a free initial consultation?

We will be happy to help you.

Enclosure labeling FAQ

Which marking is suitable for enclosure labeling?

Which marking is suitable for enclosure labeling?

Terminals, labeling strips, plastic signs and labels are suitable for enclosure labeling. It is particularly important to pay attention to the material, mounting method and durability of the products (incl. laser vs. thermal transfer printing method). The item should be easy to remove from the roll for simple installation and be available in large quantities. The material should also be resistant to chemicals, solvents and UV rays at the place of use. Depending on the item and size, the label can be printed with a name, image, logo, text or other enhancements. Signs, for example, are more suitable than terminals, as they offer more space for printing. The circuit diagram should show the exact position of the individual components and information on the circuit symbols.

How does the transfer of data work with panel labeling?

How does the transfer of data work with panel labeling?

With our Texit articles, data transfer is easy via one of the many interfaces of our thermal transfer printers. Whether Excel file or Access table, whether image, logo, text or another element. All data can simply be transferred from the carrier to the Texit Designer label software and arranged on the labels or label strips as required using drag and drop. This is one of the major advantages of Texit thermal transfer printer printing systems.

What is the function of equipment labeling for components?

What is the function of equipment labeling for components?

Equipment identification is used to clearly identify components in an assembly throughout their entire life cycle and ensures clear structuring in circuit diagrams and systems. It facilitates maintenance and servicing, as technicians can locate components more quickly and assign them without errors. It also ensures standard-compliant documentation in accordance with DIN EN 81346, which improves the comprehensibility and comparability of technical documents. In automation and digitalization, it supports integration into digital systems such as ERP or maintenance software. It also minimizes the risk of mix-ups or operating errors, thus contributing to safe and efficient operational management.

How can I implement equipment labeling for components with software?

How can I implement equipment labeling for components with software?

With the Texit Designer 11 label software, you can easily create the markings for the components and send the corresponding templates to the printer. This makes marking in the control cabinet child's play. The necessary information can be taken from the circuit diagram and the Texit Designer 11 software has an integrated Excel connection for quick and easy creation of templates.

You can order the software quickly and easily online or send us an e-mail with your request and we will be happy to advise you personally on the software.