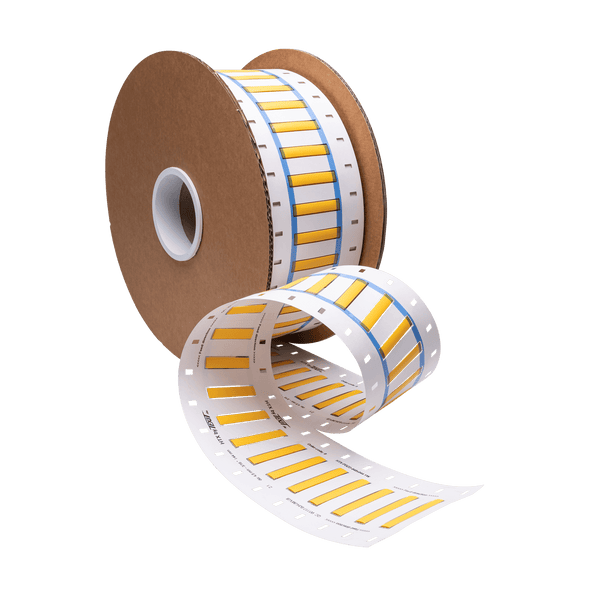

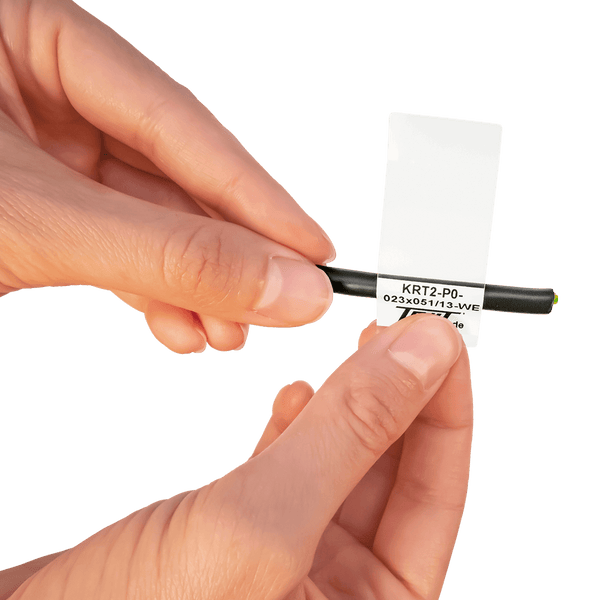

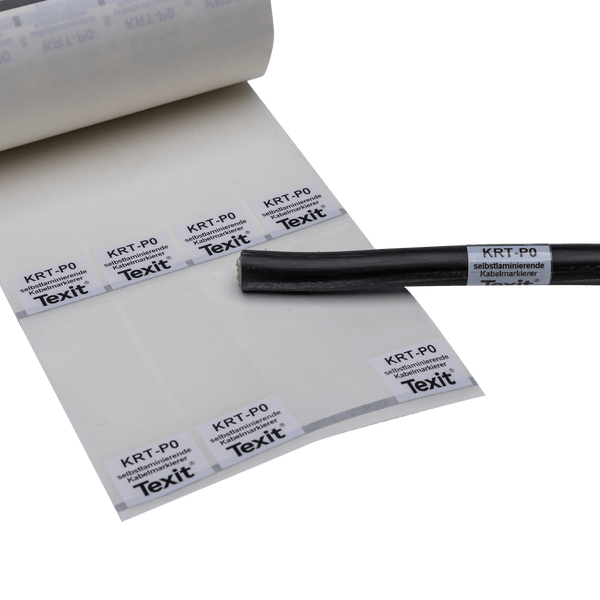

Label shrink tubing

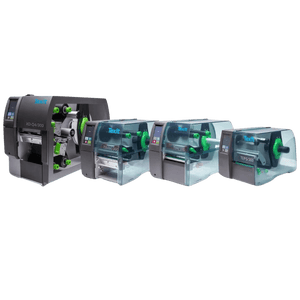

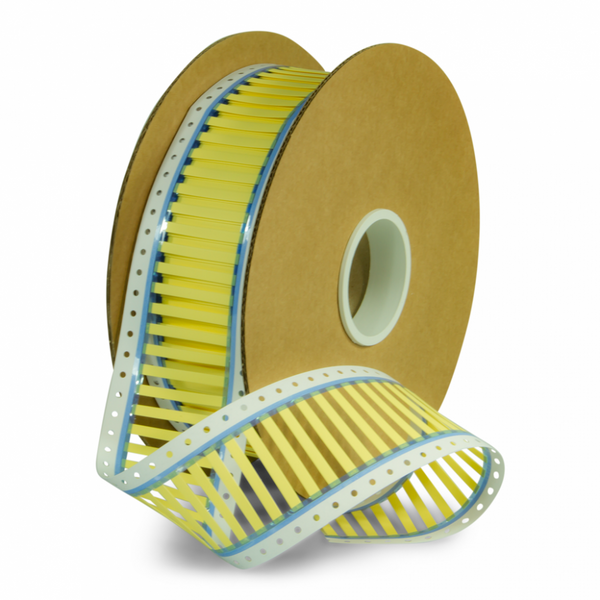

For permanent cable labeling are suitable printable shrink sleeves particularly well. You need special shrink sleeve markers for labeling. These can be marked quickly and easily using the thermal transfer process and can then be attached to the corresponding cables. The cable marking with shrink sleeve markers is highly durable and can be applied to various cable diameters with a perfect fit. Thanks to the use of high-quality polyolefin plastics, shrink sleeves are particularly robust and resistant.

And with our new Texit Designer software all shrink sleeves can be designed and printed quickly, easily and flexibly as required.

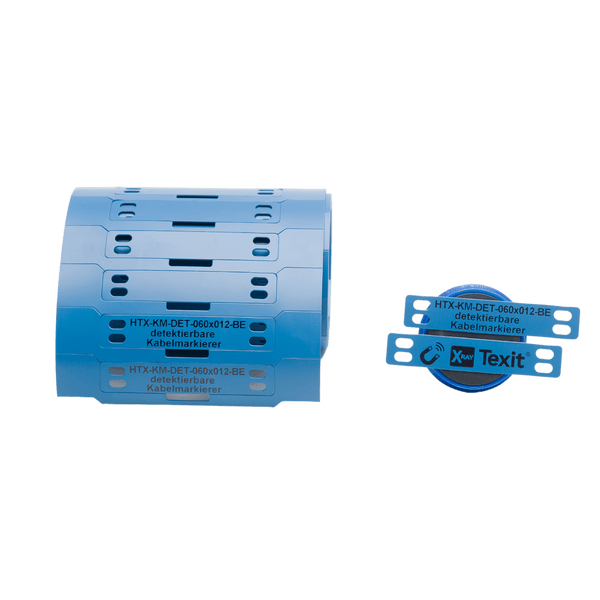

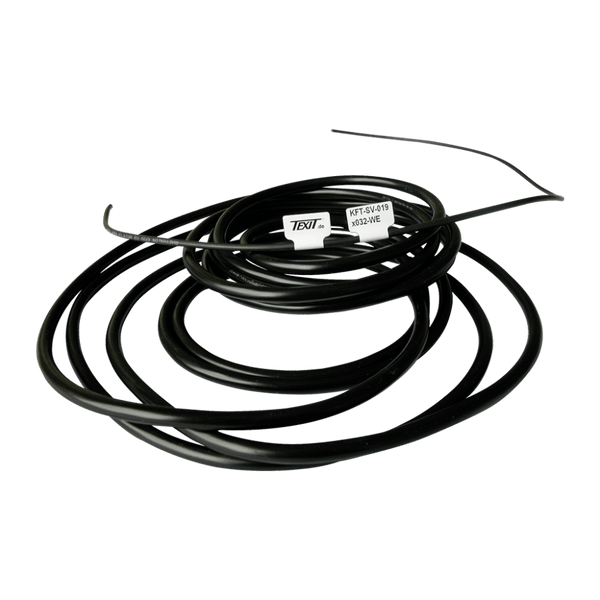

Cable signs

Cable labels are used for clear cable identification and conductor marking. The cable label is attached to the individual cables using cable ties. Thanks to their long durability and high load-bearing capacity, the labels are particularly suitable for the permanent labeling of cables in industry. They are available in different materials (plastic, stainless steel, etc.) and colors. This means that color coding can also be implemented very well for marking. You can receive free samples of all our cable label products.

All cable labels can be designed easily and flexibly with our new Texit Designer 11 software. Simply call up the right template using the search function and get started.

Also discover the Texit cable labels online on our website!

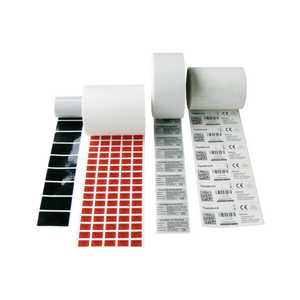

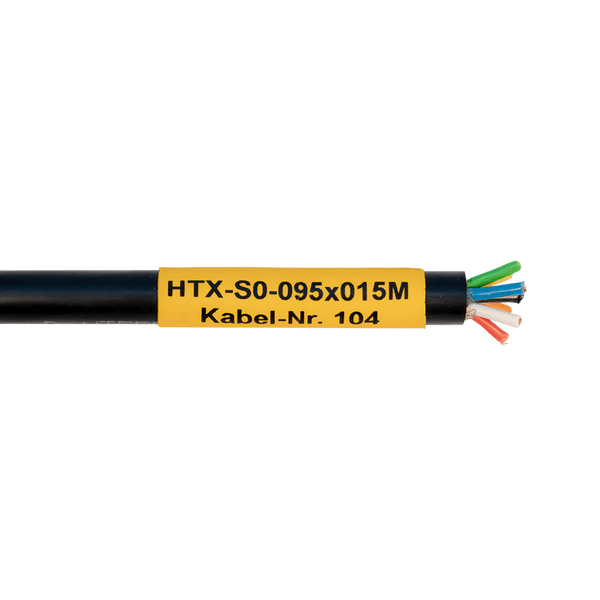

Cable labels

Cable labels are all markers for cable labeling that are attached to the corresponding cables and wires using adhesive. Many different products fall into this group of cable labeling. All Texit cable labels are already provided with adhesive and are therefore self-adhesive. Depending on the product, the labels for cables and wires can be individually printed either with a thermal transfer printer or with a standard laser printer. As the standard cable labels are wrapped around the cables, the width of the lettering depends on the respective cable diameter. If you need more space, our cable flags are best suited. Cable labels are ideal for labeling network cables.

With our new label design software, cable labels can be designed and printed quickly, easily and flexibly as required.

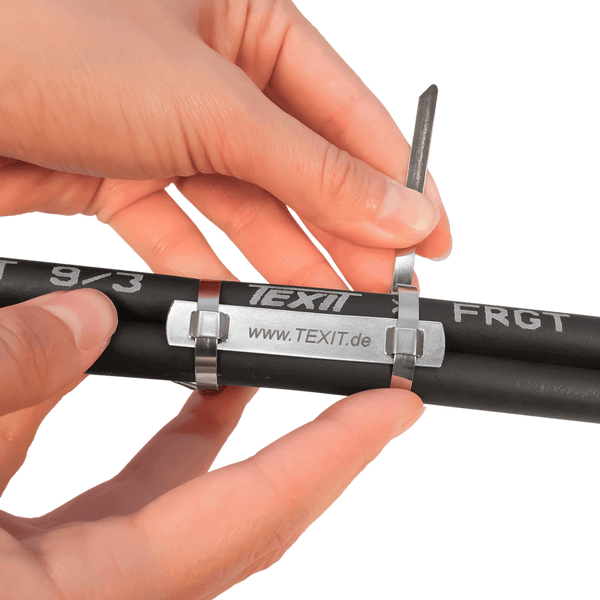

Core identification

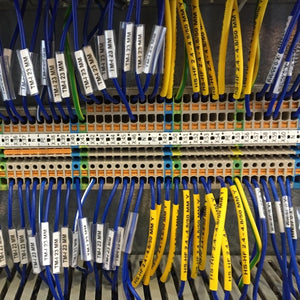

The term wire marking refers to all types of markers for cable labeling that are specially designed for small cable cross-sections and wire diameters. The markers are typically attached by clipping on, sliding on or threading on. The durable plastic markers from Texit are highly resistant to environmental influences and mechanical stress and are perfect for implementing legal and standard-compliant color coding (also suitable for single wire marking ).

FAQ Labeling cables with cable markers

What is the best way to label cables?

What is the best way to label cables?

The following 4 options are particularly suitable for cable labeling:

1. shrink tube marker

2. cable labels

3. cable labels

4. wire identification

You can use these methods to label your cables so that they are permanently legible. Cable labeling in small or private areas is best done manually with cable tags or cable labels. You can purchase small quantities and label them quickly and easily. In industry, or if extensive product information is required on the cables, robust and permanently legible cable labels are suitable. Sleeves (shrink sleeve markers), for example, are often used in control cabinets. You can add this marking to your shopping cart and order it as a printing system (set) from Texit. Thanks to our fast shipping, our wide range of products will be with you within a few days.

Why cable labeling?

Why cable labeling?

Cable labeling, such as adhesive labels, contributes to a safer and more efficient working environment for companies. It minimizes the risk of misconnections and facilitates troubleshooting and the quality of maintenance, as the information allows technicians to quickly identify the right cables in different situations (keyword efficiency). In complex installations, it supports the organization and management of cable bundles. It also helps to comply with standards and regulations and provides clarity for large projects (indoors and outdoors). Cable labeling is also helpful for extensions or conversions in order to better understand and adapt existing installations and environments.

Who is Texit cable marking suitable for?

Who is Texit cable marking suitable for?

Our range of cable labeling products is particularly suitable for electricians and tradesmen looking for quick and flexible labeling solutions for their work. IT technicians and network builders also have a great need for permanently legible (transparent) cable labels. For machine and plant manufacturers, we offer flexible printing system solutions that are especially suitable for identifying industrial cables. For building technicians, we have purpose-oriented labels for cables in order to be able to label connections and power lines in accordance with standards.

In summary, Texit cable marking is suitable for:

- Electricians

- Mechanical engineer

- Plant manufacturer

- IT technician

- Building technician

In our webshop, you can use filters or our product finder to create an overview of suitable items in the various categories. This makes it easier for you to select the cable marking. On the product pages you will find a video on the application and information and technical data on the markers as downloads.

We offer a large number of our products in various sizes (height and width) and colors (including white and yellow, but also many other colors). Many items can also be used for pipes and cables.

Where is Texit labeling for cables used?

Where is Texit labeling for cables used?

Our cable marking is widely used in industry. Machine builders use our cable markings to label their electrical and electronic systems safely, easily and in accordance with standards. Our shrink sleeves are particularly common in switch cabinet construction and in production systems for labeling sensor, control and supply cables.

Electrical installers use our cable markers to prevent cable mix-ups during subsequent maintenance work and to ensure the safety of electrical installations. Texit markers can also be used to label cables, wires, conductors and cable bundles so that they are permanently legible.

We also have suitable cable labels in our range for IT technicians and network builders to label patch cables and network cables or for labeling cables and components in network and distribution cabinets.

In summary, Texit cable labeling can be found in the following sectors:

- Photovoltaics

- Chemical industry

- Railroad industry

- Switch cabinet construction

- Defense & Military

- Wind turbines

- Plant engineering

- Mechanical engineering

- Telecommunications cabling

- IT & EDP cabling

- Event technology

What do the labels on the cables mean?

What do the labels on the cables mean?

The markings on electrical cables generally follow a standardized system of letters and numbers that provide information about the standard, structure, insulation, sheath, number of conductors and conductor cross-section.

An example of such labeling according to the VDE standard 0250, which is common in Germany, is: NYM-J 3x1.5

N → according to standard cable (standardized according to VDE)

Y → PVC insulation of the cores

M → sheathed cable with plastic sheath J → with green-yellow protective conductor (without protective conductor it would be -O)

3x1.5 → three cores with a cross-section of 1.5 mm² each