Industrial wire marking according to standard

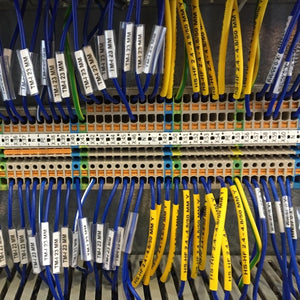

In industrial electrical engineering, clear and standard-compliant wire identification is essential - for safety, maintenance and efficient wiring. In our range, you will find high-quality wire marking products that comply with the most important standards in Germany:

For control and signal cables, the color coding according to DIN 47100 is widely used - with up to 44 clearly defined wire colors. For energy and power cables, the binding specifications of VDE 0293-308apply, e.g. green-yellow for the protective conductor and blue for the neutral conductor.

In addition, we offer labeling solutions in accordance with DIN EN 60204-1 (mechanical engineering), DIN EN 81346-2 (systematic conductor marking) and DIN EN 60445 (international color coding). Whether you need colored wire leads, clips, shrink sleeves or pre-printed labels for direct use - as a manufacturer of industrial wire labeling, we offer a wide range of products as well as personal advice from our labeling experts!

Types of core markings

Since the topic of wire marking is very extensive, we have summarized the most important types for marking and identifying wires and conductors for you here. Click to get more information about the individual options.

Core labeling

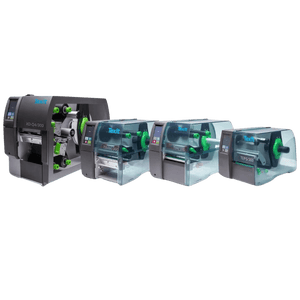

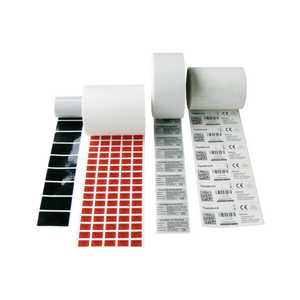

Our ART wire markers are perfectly suitable for the marking of wires and single wires. The thin wire markers in the size 20x6mm can be printed quickly and easily with the thermal transfer process. Thanks to the high-quality PE film, these wire markers are halogen-free and particularly flexible. This facilitates the assembly.

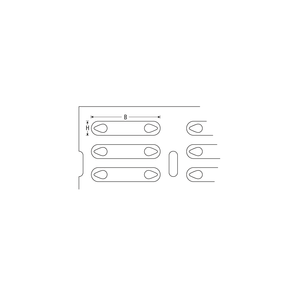

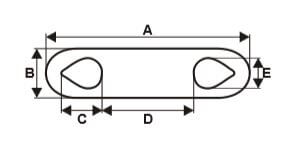

Marking carrier for wire marking

The MultiTex marking carriers from Texit are special holders for fixing the ART wire marking. They are available in 2 versions: the standard AMT variant and the halogen-free AMT-PZ variant. The carriers allow the marking to be easily attached to the individual cores.

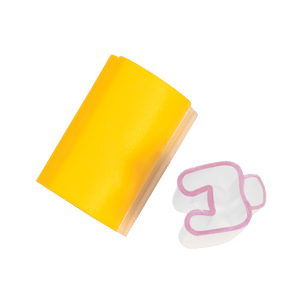

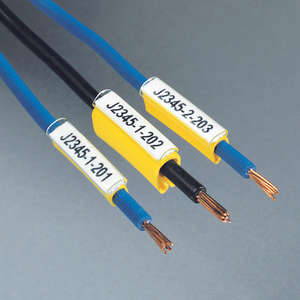

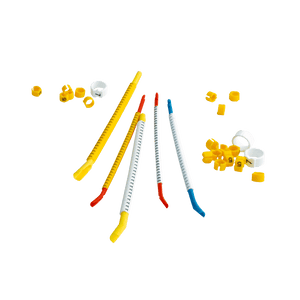

Cable labelling clips

Cable marking clips are an excellent way to mark thin cables and single wires even after cable assembly. The cable clips are made of polyoxymethylene (POM for short) and are therefore halogen-free, UV and temperature resistant. The clips (embossed according to your wishes) are supplied on mounting rods and can be easily pushed from there onto the cables and cores.

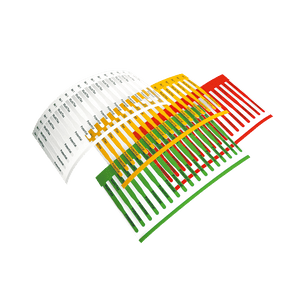

Wire marking

Texit's wire markers DRT are specially designed for marking wires, cores and thin cables. The flexible markers made of PET film can be printed well with the thermal transfer process and can be easily threaded onto the corresponding wires (cable ties or glue as with labels is not necessary).

Core marking with Texit ART markers

FAQ Wire labeling industry

What wire colors are prescribed for wires and cables?

What wire colors are prescribed for wires and cables?

The wire colors prescribed for cables and wires depend on the area of application in which the cables and wires are used:

Mechanical & plant engineering:

- Green-yellow for the protective earth conductor (PE)

- Blue for the neutral conductor (N)

- Black number identification (e.g. with rings or shrink tubes) for control circuits. DIN 47100 can also be used if it is necessary to differentiate between many control wires by color.

- VDE 0293-308 is relevant here. It specifies

- Green-yellow = protective conductor (may only be used for this purpose!)

- Blue = neutral conductor

- Brown / black / gray = outer conductor (L1, L2, L3). These color codes are mandatory for all power and installation cables.

Telecommunications technology:

- DIN 47100 is often used here, especially for telephone lines

- Control cables with many cores (e.g. 10-44 cores). This standard provides a defined color table with individual colors and color combinations for clear identification of each wire.

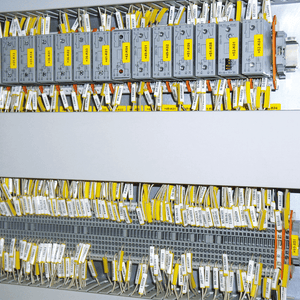

Electrical engineering in switch cabinet construction:

- Color coding according to VDE 0293 / EN 60204-1

- Numbering using wire markers, marking rings or printable shrink sleeves (e.g. in accordance with DIN EN 50334). This ensures clarity and standard-compliant maintenance.

At Texit, as a specialist in industrial cable marking, we have suitable products in our range for all the industries and users mentioned. If you have any questions about compliance with standards, our marking experts will be happy to advise you individually and personally.

Which wire is L1, L2 and L3?

Which wire is L1, L2 and L3?

The cores L1, L2 and L3 are the three phase conductors (outer conductors) in a three-phase system. According to the VDE 0293-308 standard, they are color-coded as follows:

L1: Brown

L2: Black

L3: Grey

These colors also apply:

Neutral conductor (N): Blue

Protective earth conductor (PE): Green-yellow

This color coding is mandatory in electrical installations to ensure clear assignment and maximum safety.

What color is wire no. 4 according to DIN 47100?

What color is wire no. 4 according to DIN 47100?

Wire no. 4 according to DIN 47100 has the color yellow.