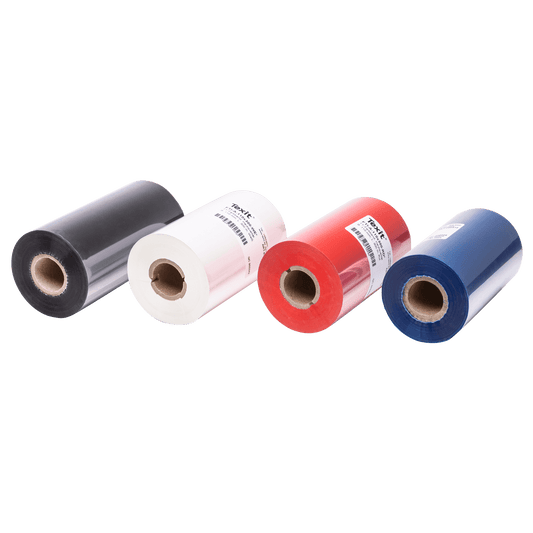

Thermal transfer ribbons: The right choice

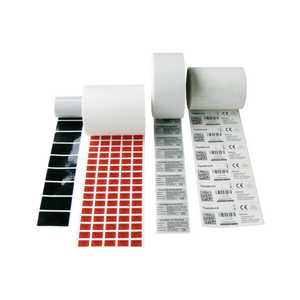

Very durable and robust printing results can be achieved with the thermal transfer printing process. The prerequisite for this is not only the choice of the right material and printer, but also the choice of the right thermal transfer ribbon. In this thermal printing process, the ribbons serve as a carrier material for the ink. This is why they are also called ribbons as consumables. Depending on the material of the cable labelling or industrial labels and the requirements, a specific ribbon is needed for printing.

Your individual requirements

First of all, of course, the individual requirements at the place of use for the print play a major role. What colour do you need for the lettering? What about sizes (widths & lengths)? What are the temperatures at the location? What do the print results have to be resistant to?

The quality of the thermal transfer ribbon

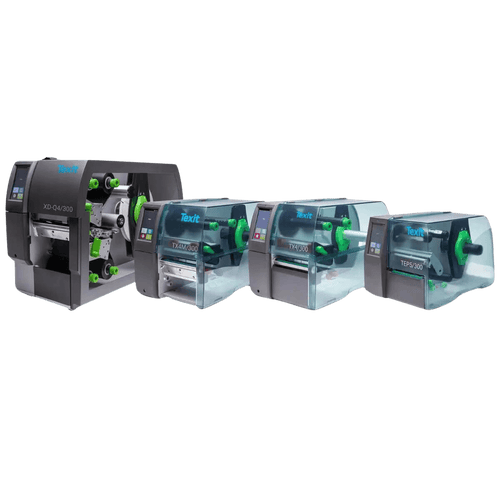

The quality of the thermal transfer ribbons can already be narrowed down on the basis of the requirements. In the case of ribbons, a basic distinction is made between three qualities: Wax, wax-resin and resin. These materials are solvents for the ink layer. It is important that the quality of the ink ribbons is exactly matched to the requirements at the place of use. At Texit you can combine all thermal transfer ribbons with all Thermal transfer printers combine them. Therefore, the printer model does not matter when looking for the right thermal transfer ribbon. If you still have questions about choosing a thermal transfer ribbon, you can always contact us via the form on our website. We will be happy to advise you!

Wax ribbons

A thermal transfer ribbon made of wax has the lowest quality level. It is only used for printing on paper labels, as the smudge and scratch resistance of wax is not very high. For plastic labels or cable markers, you cannot achieve a high-quality print with a wax thermal transfer ribbon. For this you need a higher quality ribbon. Since we at Texit specialise in permanent marking, we do not offer wax-based ribbons in our range.

Wax-resin ribbons

Ribbons for thermal transfer printers made of a wax-resin mixture have a higher smudge and scratch resistance than pure wax ribbons. These so-called mixed ribbons combine the advantages of both materials. The wax content ensures a relatively low melting point of the ink layer. The resin content gives the film good smudge and scratch resistance and thus increases the robustness of the print results. Therefore, mixed films may also be suitable for use in industry. We recommend the use of such a mixed ribbon to our customers in the railway industry when printing the halogen-free shrink sleeve markers.

Resin ribbons

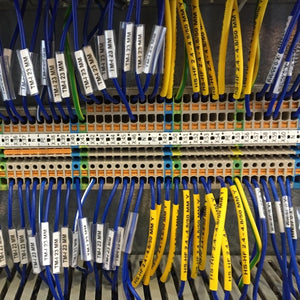

Resin thermal transfer ribbons have the highest quality and also the highest smudge and scratch resistance. Printing with these films is resistant to alcohols, petrol, oils and other chemicals. The ink layer also withstands very heavy loads and is therefore best suited for industrial use. Such a ribbon is the optimal solution for durable industrial labels and cable marking. This quality level can be used for many different plastic materials. Our high-quality FTI-Y and FTI-B thermal transfer ribbons are ribbons of this quality level.

The material to be printed

The thermal transfer ribbon must of course also be matched to the material to be printed. Plastic labels are best printed in industry with wax-resin or resin ribbon. The same applies to plastic products for cable labelling. Depending on the individual label or cable marker, different products are also suitable within one ribbon quality.

Thermal Transfer Ribbon Advice

Choosing the right thermal transfer ribbon is very important because the ribbon has a significant influence on the print quality. Since the decision is not only dependent on the material, but also on your individual requirements, we are happy to support you here. Thanks to our many years of experience, we know what has proven itself in practice and will be happy to advise you individually on the right printing system for your requirements. Get in touch quickly and easily via the contact form on our website, give us a call or send us an email. Together we will find the optimal labelling solution.

Structure of the thermal transfer ribbons

The thermal transfer ribbons consist of three different layers: the back coating, the carrier material and the ink layer. The interaction of these layers enables the optimal printing of the thermal transfer labels & cable markers.

The back coating serves as protection for both the print head and the labels. It is made of silicone and acts as a protective layer in both directions. It prevents build-up and contamination on the print head and at the same time protects the material to be printed from excessive heat. Since silicone is a very smooth material, the back coating also ensures that the film glides smoothly in the printer.

The backing material for the thermal transfer ribbons is made of polyester. The polyester film serves as a double-sided carrier, both for the ink layer and for the reverse side coating. It allows good release of the ink during printing.

The ink layer is a solvent that contains the inks for printing. The material of this film depends on the respective quality level. During the thermal transfer printing process, the individual ink particles are melted onto the labels / cable markers. Depending on the quality of the ink layer, printing results with very high durability and smudge and scratch resistance can be achieved.

Thermal Transfer Ribbons FAQ

Every day we receive many questions regarding the different thermal transfer ribbons and our thermal transfer printing systems. In order to be able to help you in advance, we have created an overview with the most frequently asked questions and answers. If you have additional questions or need further information, you can always contact us via the Contact form on our website. We will be happy to advise you on all aspects of industrial labelling.

Load thermal transfer ribbon into printer

Frequently asked questions about thermal transfer ribbons

Which thermal transfer ribbon is available?

Which thermal transfer ribbon is available?

Thermal transfer ribbons, also called ink ribbons, are basically distinguished between three different qualities: Wax, resin and a wax-resin mixture.

Wax foils have a low melting point and require little energy to print. However, the printing results are less durable and not many materials can be printed with wax ink. Resin films, on the other hand, have a high melting point and therefore require more energy to print and deliver very robust and durable results. Wax-resin blended films combine the two advantages of the materials and thus form an intermediate level of quality.

What is thermal transfer printing?

What is thermal transfer printing?

In thermal transfer printing, the ink is melted by applying heat to the material to be printed. The thermal transfer printer transfers the ink from the thermal transfer ribbon to labels / cable markers or other plastic materials with pinpoint accuracy using heat. The results are very durable. This makes thermal transfer printing ideal for permanent labelling in industry.

Thermal transfer printing is one of the thermal printing processes. In addition, there is also direct thermal printing and dye sublimation printing. You can find more detailed information on how the thermal transfer process works at our Thermal transfer printers.

What is direct thermal printing?

What is direct thermal printing?

In direct thermal printing, heat is used to catalyse a chemical process in the printing material, which produces a colour change in the material. This printing process therefore works without separate ink. Direct thermal printing, like thermal transfer printing, is a thermal printing process. The print results with this process are not as durable as with the thermal transfer process and are therefore only suitable for permanent labelling to a limited extent. In addition, only specially treated material can be printed with this type of printing.