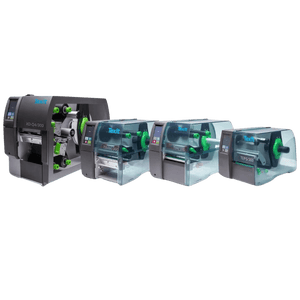

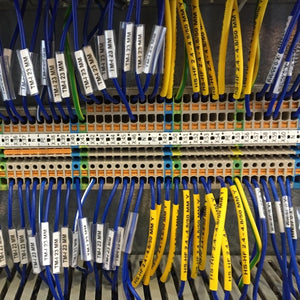

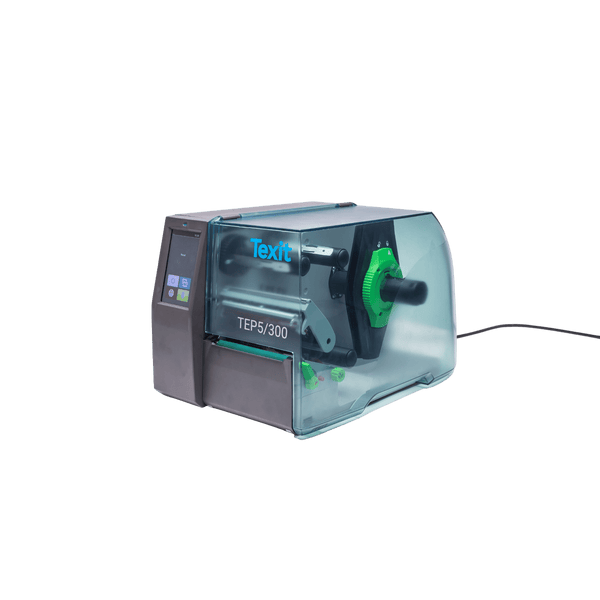

At Texit, we have various thermal transfer label printers in our range. Depending on your needs, you can choose between entry-level models for occasional or small requirements and high-performance industrial printers for large print volumes. All of our thermal transfer printers can also be used to print cable markers, shrink sleeves or type plates. The printers are therefore not limited to printing labels, but can be used for a wide range of applications. In the thermal transfer printing process, the ink layer is melted onto the labels by applying heat to specific points. This creates an extremely precise and robust print image. At the same time, you also need a suitable ribbon for printing. We will be happy to help you make the right choice. Simply contact us for a free, individual consultation.

Texit industrial label printer in comparison

To make it easier for you to choose the right thermal transfer printer, we compare our Texit printer models here. You can also find a comparison table of the models on our thermal transfer printer category page.

Print resolution & print speeds

The print resolution of all our thermal transfer printers is 300 dpi. This high resolution is necessary for a clean print image and good printing results. 300 dpi means that 300 halftone dots are printed per inch. This number of dots is sufficient for the human eye to feel comfortable at a normal viewing distance (approx. 25 cm). 300 dpi is also the standard resolution for label printing with this printing technology.

Our thermal transfer printers differ in terms of print speeds. Our TEP5 (our entry-level model) has a print speed of up to 150 mm/second, while the XD-Q4 double-sided printer only has a print speed of up to 125 mm/second. For higher print volumes, we therefore recommend our TX4 & TX4M printer models: these can achieve print speeds of up to 300 mm/second. This means that even high volumes of thermal transfer labels can be printed quickly and cleanly with these devices. All printers have a print width of 105.7 mm.

Available interfaces

All of our 4 thermal transfer printers have a variety of interfaces for connecting to the computer and loading data from databases. You have the option of integrating Excel data, for example, by using the appropriate interfaces. Choose between USB host, USB interfaces (e.g. for memory stick), Ethernet 10/100 Base, SD card, network connection (WLAN or serial or LAN). This variety of interfaces makes the printers so easy to use. The USB host interface is particularly popular with our customers. With the USB host, a lot of data information of different types can be connected quickly.

Flexibility in use or intended use

There are also differences in the flexibility of our printer range. For example, not all models can print continuous label material. Only the TEP5, the XD-Q4 and our TX4M can do this, as they can feed the material centrally. The TEP5 is not suitable for continuous, heavy-duty industrial operation, but rather for small or occasional requirements. We particularly recommend our TX4 & TX4M thermal transfer printers as industrial printers. These two models are ideally suited for use in industry, as they are high-performance, robust and have a long service life (even with continuous daily use). Nevertheless, all label printers can also be used as type plate printers or test badge printers without any problems.

Thermal transfer printers vs. direct thermal printers

Thermal transfer printers and direct thermal printers both belong to the category of thermal printers. They both use selective heat to create the printed image. Nevertheless, the two processes differ greatly in their application:

Thermal transfer printers use a ribbon that is coated with wax, resin or a mixture of both. In thermal transfer printing, the ribbon is heated in the printer's print head by applying heat at specific points, which melts the ink from the ribbon onto the label material. The print results are extremely robust and have very high durability and abrasion resistance. They are also UV-resistant (depending on the label material used). Thermal transfer printers are particularly suitable for printing long-lasting labels, as the printed image is more resistant to abrasion and environmental influences. They are often used in applications where high print quality and durability are required, such as barcode labels for stock or labels that are permanently used outdoors. A major advantage of the thermal transfer printing process is that a wide range of different label materials can be printed on.

Direct thermal printers do not use ribbons. Instead, they print directly onto specially coated label material. In the direct thermal printing process, the printed image is created by a chemical reaction in the label material itself. This is why only very specific materials can be printed on using this printing method. The label material contains a special coating that reacts when heated by the printer's print head and creates the printed image. As no ribbons are used, there is no need to replace them regularly, which reduces operating costs. At the same time, however, direct thermal printing is not very robust and certainly not UV-resistant. Direct thermal printing is therefore particularly suitable for short-life labels, such as shipping labels or receipts.

Overall, both printing technologies are useful in different applications, depending on the print quality and durability requirements.

Application Desktop label printer

Our thermal transfer printers are extremely easy to use. You will receive installation and operating instructions on delivery. We also have video instructions for the Texit printing systems on our website. Here we show you step by step how to get the thermal transfer printer up and running and how to load the various materials.

Whether conventional film labels, special thermal transfer labels or accessories such as cutters and perforators: all of these can be set up (integration) or inserted in no time at all and are then ready for use. As a rule, companies manage to set up their printing systems themselves. However, if you have any questions or if you wish, your regular Texit contact will be happy to visit you on site and install the system for you. These services are free of charge with our Texit service and are included for you as a customer.

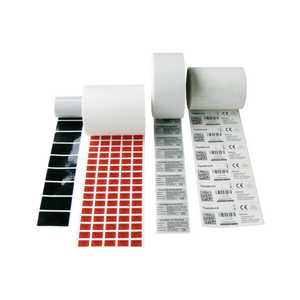

Thermal transfer label printer accessories

You will need additional accessories for printing with the thermal transfer label printer. If you do not yet have any labels, you will first need to choose the right label material. This depends primarily on your requirements and where the labels will be used. You will need high-quality ribbons to match the label material. The label software for designing the print on the desktop rounds off the printing system. Now you can get started.

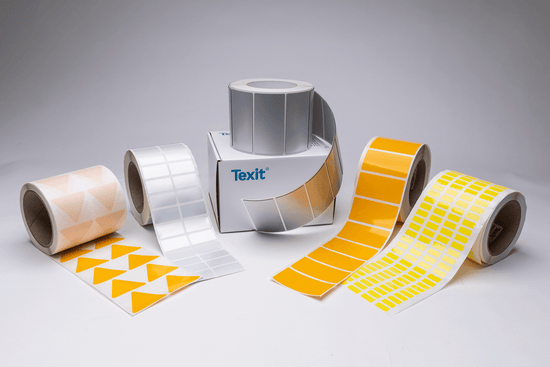

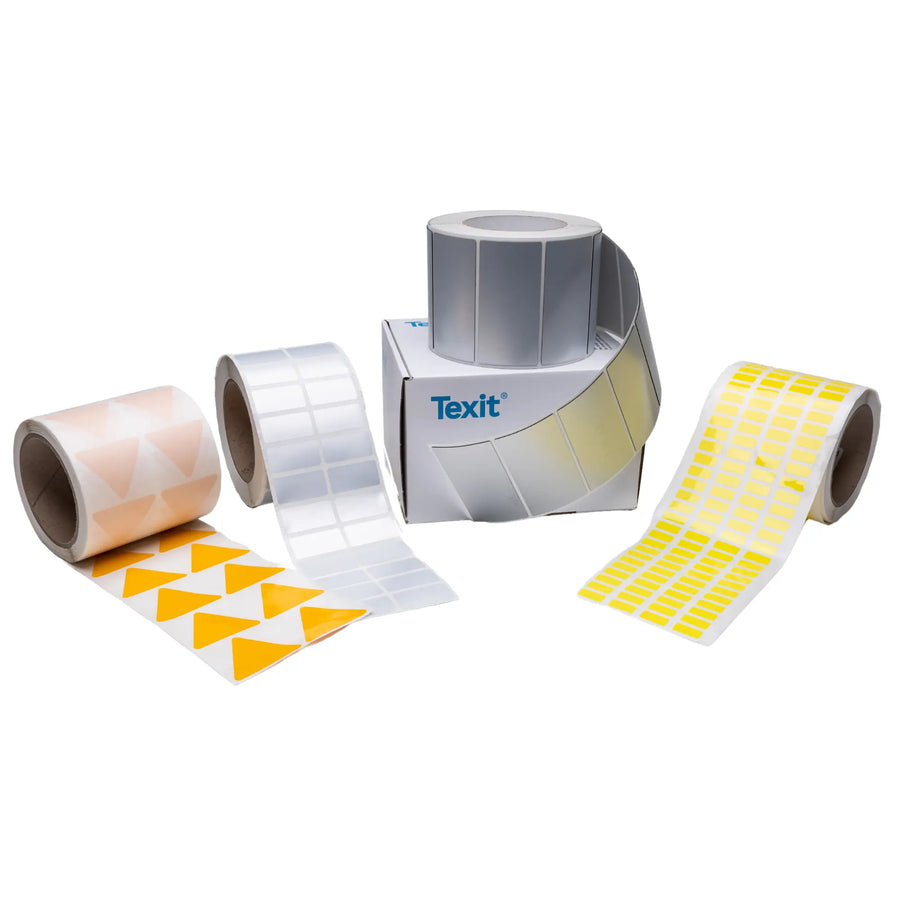

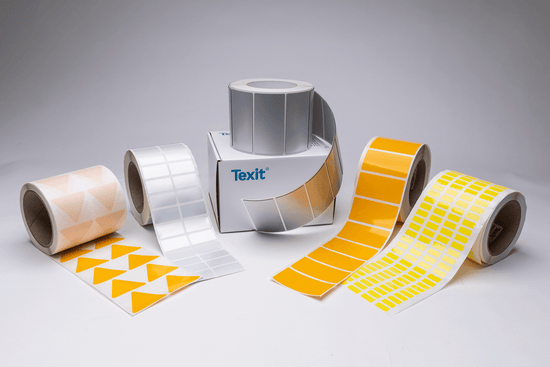

Thermal transfer labels

Thermal transfer labels are usually made of plastic films. You have various options to choose from in our range, including polyester, vinyl and polyamide. Each material has different properties and should be carefully matched to the conditions on your site. We offer help and support with the optimal choice of material for your industrial labels - simply contact us.

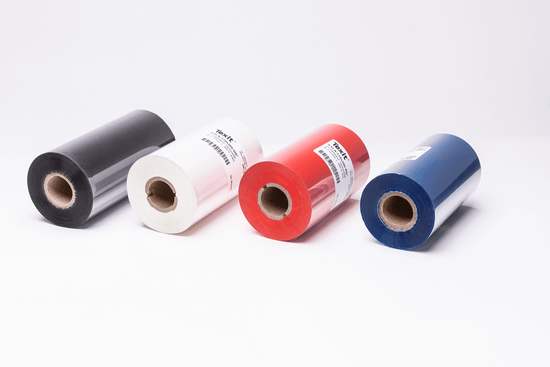

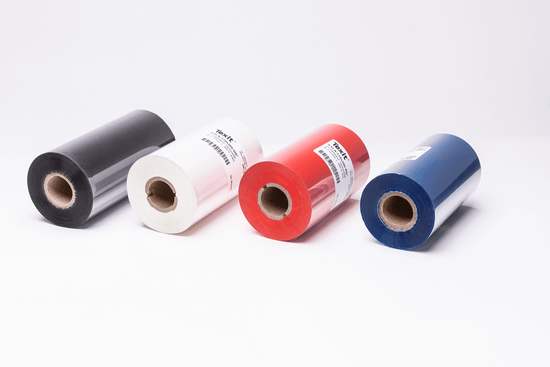

Ribbons

The selection of a suitable ribbon is essential for thermal transfer printing. This is the only way to achieve an optimum print result and produce a clean print image. At the same time, the choice depends primarily on the label material. Thermal transfer ribbons are divided into different quality levels: Wax, resin and a wax-resin mixture. On the product page of our thermal transfer ribbons you will find further information on compatibility with the labels.

Label software

Last but not least, you need the right label software to create the design. At Texit, we rely on the user-friendly software from Nice Label. Here you have the option of choosing from 3 packages, depending on the requirements you need for the design. Detailed information on the various software packages can be found on the software overview page in the printing systems section.

-

Thermal transfer labels

-

Thermal transfer ribbon

-

Labeling software

FAQ Thermal transfer label printers

What advantages does the thermal transfer label printer offer over a direct thermal printer?

What advantages does the thermal transfer label printer offer over a direct thermal printer?

Thermal transfer and direct thermal printers differ in the way they work and each offer specific advantages. A key advantage of the thermal transfer printer is the durability of the labels. Thermal transfer printing produces labels that are resistant to abrasion, moisture, chemicals and UV radiation. This is ideal for applications where labels are exposed to harsh conditions or need to remain legible over a long period of time, unlike direct thermal labels which fade over time and are less resistant.

Another advantage is the versatility of the materials. Thermal transfer printers can print on a variety of materials such as paper, polyester, polypropylene and other synthetic materials. This versatility allows them to be used in a variety of industries such as logistics, retail, manufacturing and healthcare. Direct thermal printers, on the other hand, are usually limited to coated thermo-sensitive paper, which restricts their areas of application.

In terms of print quality, thermal transfer printers offer greater precision and sharper images and text. This is particularly important for labels that need to contain barcodes or other detailed information. Although direct thermal printers deliver good print quality, they do not achieve the consistency and precision of thermal transfer printers.

Another advantage of thermal transfer printers is the flexibility in ribbon selection. They allow the use of different ribbon types such as wax, resin or wax-resin mixtures to meet specific durability and print quality requirements. Direct thermal printers do not have this option as they do not require a ribbon.

Thermal transfer printers are particularly suitable for special applications that place high demands on durability and resistance, such as inventory labels, type plates, industrial labeling and long-term outdoor labeling. Direct thermal printers, on the other hand, are better suited to short-term applications such as shipping labels, receipts and tickets where the labels do not need to last long. In summary, thermal transfer printers offer more flexibility and durability, making them the better choice for demanding and long-lasting labeling applications.

Which thermal transfer ribbon do I need for the label printer?

Which thermal transfer ribbon do I need for the label printer?

You have various options when selecting the color ribbons. The selection always depends on the label material. For example, there are wax-based and resin-based thermal transfer ribbons and a mixture of both (wax-resin ribbon). A thermal transfer ribbon or thermal transfer film is required to transfer the ink to the labels. It serves as a carrier material for the ink. We are happy to offer you our help in selecting the right ribbons. Our labeling experts are always available to advise you on your individual requirements.

You can also find an overview of which thermal transfer ribbons we recommend for which products on our thermal transfer ribbon product page.

What interfaces do the Texit thermal printers have?

What interfaces do the Texit thermal printers have?

The Texit thermal transfer printers have 2 USB master interfaces for connection via USB 2.0 (network, Wlan, Lan or serial), scanner or memory stick (also suitable for connecting an external keyboard) as well as an Ethernet 10/100 interface, an SD interface and USB host. You can find more information on the respective printer product pages.

Which materials can be printed on with a label printer?

Which materials can be printed on with a label printer?

Our Texit thermal transfer printers can be used to print on a wide range of products and materials. Plastic label materials are usually printed with a thermal transfer printer because this combination delivers the best printing results. The advantages are obvious: print results with outstanding properties, UV light-resistant markings, marking of 2D barcodes and much more. And all tailored to your individual needs!