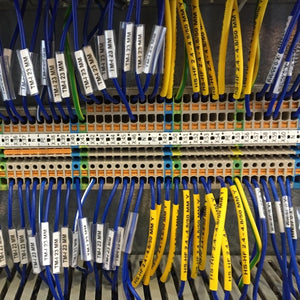

The clear and standard-compliant marking of power cables is an essential rule for the safe, traceable and efficient installation and maintenance of electrical systems and devices in industry. Clear marking not only enables quick identification of the individual wires, cable types and current conductors, but also minimizes the risk of errors during connection and maintenance. The marking systems must comply with the applicable standards and guidelines, such as DIN VDE, and be selected taking into account the respective operating conditions. The investment in high-quality and standard-compliant cable marking pays for itself by minimizing downtimes and contributes significantly to the operational safety and availability of machines and systems.

The common options for marking power cables that meet the requirements for function, clarity and safety are presented below.

Options for labeling power cables

There are various categories for cable labeling of power cables. Which products are suitable for your power cables depends firstly on the requirements for cable marking (e.g. industry-specific standards and guidelines, customer requirements, but also conditions such as cable diameter or specifications regarding size or color). On the other hand, the place of use also plays an important role.

If the cables need to be labeled flexibly on construction sites, we recommend our handy TEP label printer. You can take this printing system with you and use it on site. If the power cables are permanently outdoors, the abrasion resistance and resistance of the print to temperatures and UV rays play a major role. If, on the other hand, you want to label power cables in the chemical industry, the markers should be resistant to solvents, oil and other chemicals. In the following paragraphs, we have summarized the most common methods for marking power cables:

Label power cable with shrink tubing

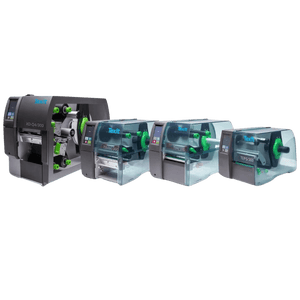

A tried and tested option for marking power cables is the use of so-called shrink sleeve markers. These special shrink sleeves are optimized for cable marking and can be marked permanently and legibly using a thermal transfer label printer. These markings are first printed and then threaded onto the corresponding power cables. The tubing shrinks when exposed to heat and adapts perfectly to the cable diameter.

As a manufacturer, Texit offers a wide range of high-quality shrink sleeve markers. These score particularly highly in terms of their durability and robustness. However, as they are not attached to the power cables with cable ties or similar aids, these markers must be applied during cable assembly.

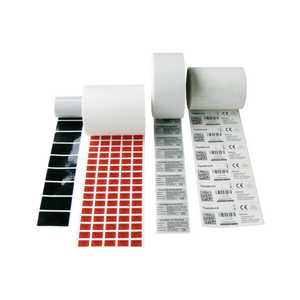

Labeling power cables with cable labels

Cable labels are another option for labeling power cables and wires. They are available in various sizes for both small and large cable diameters. Cable labels for permanent cable marking are made of high-quality plastic (e.g. polyester, polyethylene or PVC). Cable labels with an integrated protective laminate have proven particularly effective for industrial use. These labels are self-laminating and have a longer piece of laminate film after the label field, which is stuck over the label field. This ensures that the print is well protected from external influences. One advantage of using labels for cable marking is that they can still be used after installation and are therefore also suitable for subsequent marking.

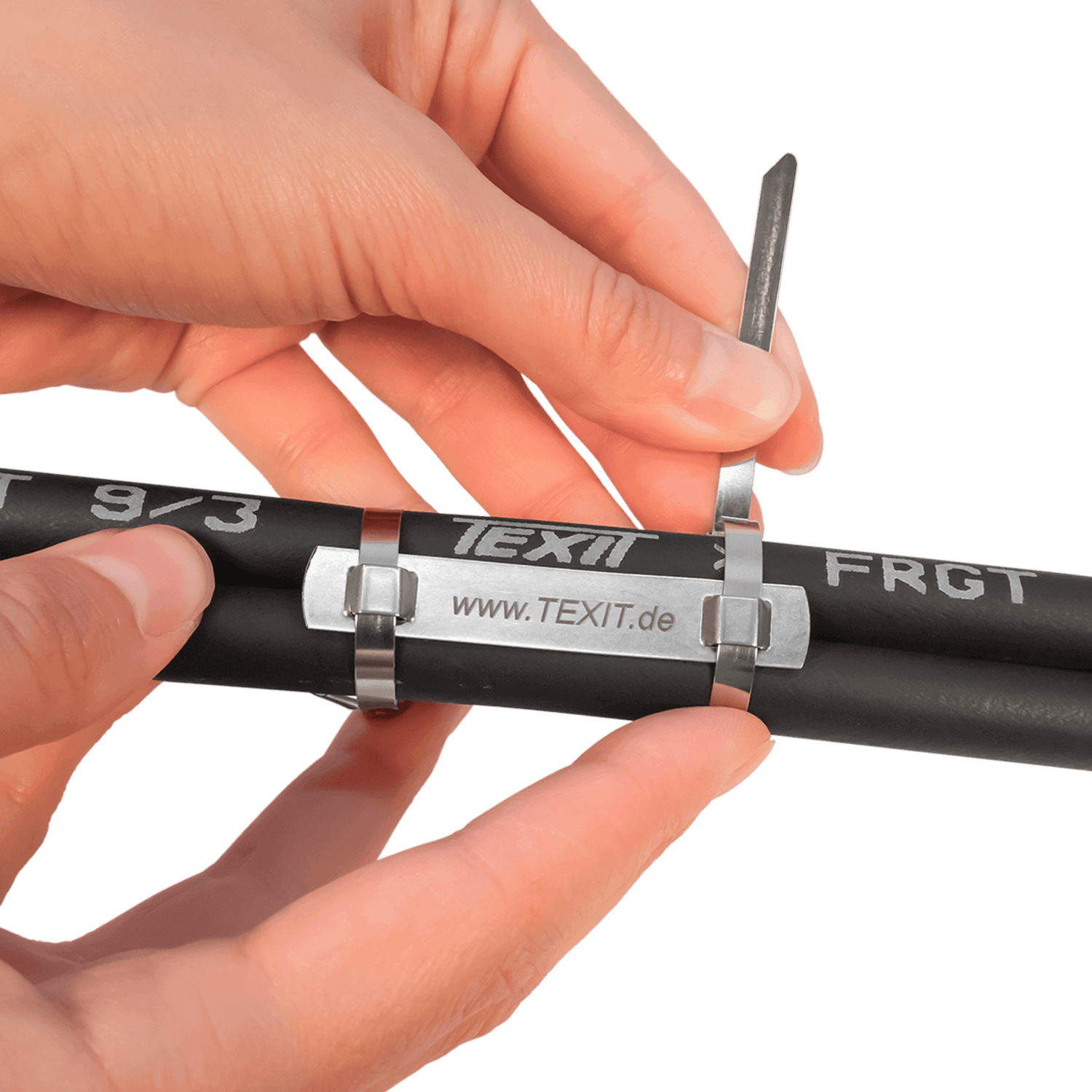

Mark power cables with cable labels

The use of cable labels is a very good solution for the permanent labeling of power cables. Cable labels are available in different materials (e.g. plastic or metal). The labels are attached to the power cables using cable ties. The size of the labeling field is therefore less dependent on the cable diameter than with labels or shrink sleeves. The cable labels can also be labeled permanently and legibly using a thermal transfer printer. They are available in various colors and, if required, also in stainless steel (which is particularly robust and resistant). In most cases, you will achieve very good results when labeling power cables using cable labels.

Markers for core conductors

Permanent cable labeling can also be applied to power cables in the form of markers or clips. This type of cable labeling is particularly suitable for power cables with smaller diameters. The marking is clipped or threaded onto the cable. Cable clips can also be attached after cable assembly and are particularly suitable for coding individual power cables. Wire markers, on the other hand, are threaded onto the cables and must therefore be attached during cable assembly. They are made from high-quality polyester film and can be permanently labeled using a thermal transfer printing system.

Do you need support with power cable labeling? We will be happy to advise you!

FAQ Labeling power cables

What is the best way to label cables?

What is the best way to label cables?

In electrical engineering, clear labeling of cables, cores and protective conductors is important in order to reliably assign different voltages, conductor types (or conductor types) and structures in accordance with DIN specifications. Certain criteria apply depending on the number of conductors, type of cable or technical requirements. The best way to label cables is as follows:

- Self-laminating labels: durable solution with imprint, particularly suitable for control cables and network installations.

- Cable ties with cable shield: ideal for thicker cables (depending on the conductor cross-section) or for many cables with different functions.

- Printable heat-shrink tubing: enables permanent, abrasion-resistant printing directly on the wire - particularly useful for high voltages or in control cabinets or for outer conductors.

- Marking clips or rings: can be attached for assignment by number, letter or function - often used in distributions.

This overview gives you a good selection of options - ultimately, the choice of system always depends on the specific purposes, specifications and criteria on site. For example, when it comes to the choice of material (ethylene propylene rubber, polyolefin compound, metal, natural rubber, PVC,...).

The labeling experts in our company will be happy to advise you personally and without obligation on optimal labeling. You can find instructions for marking electrical cables and a guide to marking electrical systems, including cable colors and cable types, on our electrical installations page.

How are cables labeled?

How are cables labeled?

In industry, clear and standard-compliant power cable marking is essential - whether for safety, maintenance or traceability in system operation. Cables and wires are labeled or color-coded according to their function, voltage, affiliation and technical properties.

Typical labeling methods are

- Labels, e.g. self-laminating, heat-resistant or UV-resistant

- Heat-shrink tubing with imprint, particularly durable and space-saving

- Color coding, e.g. for protective conductor (green yellow) or neutral conductor (blue)

- Cable clips for quick identification of individual conductors and cores

How should a company clearly label power cables to correctly identify insulation, protective conductors and technical details?

How should a company clearly label power cables to correctly identify insulation, protective conductors and technical details?

Well thought-out labeling is crucial for reliable identification and standard-compliant documentation of power cables - especially for sheathed cables, protective conductors and cables with specific requirements for rated voltage, length and cross-section.

Texit specializes in power cable marking, which has been specially developed for the permanent marking of cables and conductors in electrical engineering. Our solutions meet all relevant standards and are used in industrial environments worldwide.

You should pay attention to the following points:

- Insulation and sheath: The outer insulation or sheath of a sheathed cable can be labeled with smudge-proof, UV-resistant printing inks or robust Texit labels.

- Color coding: According to the standard, the color green yellow is prescribed for the protective conductor - special attention must be paid to a clear separation of e.g. yellow as a signal or functional color.

- Cable designation: Each marking should contain technical details such as cable type (e.g. NYM-J), length, conductor cross-section (e.g. 3×1.5 mm²), rated voltage (e.g. 300/500 V) and a clear internal company designation.

- Labeling solutions: Texit offers self-laminating labels, heat-resistant shrink sleeves with imprints and label carriers for all standard cable diameters.

Where can I get more information about cable labeling?

Where can I get more information about cable labeling?

You can find even more information on the subject of cable labeling and permanent cable marking on our website under the heading Cable labeling. There you will also find the various options and information on the respective advantages and disadvantages. At Texit, we also attach great importance to good service and a dedicated contact person for interested parties and customers. We will clarify your questions in a personal discussion and make a suitable selection of products for an individual solution for marking your power cables. Simply get in touch with us. Our marking experts have many years of experience in the industry and are very familiar with the challenges of cable marking.

Which symbol for power cable?

Which symbol for power cable?

There is no general, universal symbol that represents an entire power cable or for general identification. Instead, cables are usually drawn as lines, often with labels or color codes to identify the individual wires.

The following cable colors are common in Germany:

- Brown = phase L1 (also L1 for three-phase current)

- Black = phase L2 (second phase)

- Gray (sometimes instead of black) = phase L3 (third phase, if available)

- Blue = neutral conductor (N)

- Yellow-green = protective earth conductor (PE)

This color coding is defined in DIN VDE 0293 (Part 308) and VDE 0100, and is also relevant for cable manufacture and wire colors in DIN VDE 0281/0282/0292.