Industrial marking systems include devices, machines and tools that are used to clearly mark products and objects. Markings play a central role in modern production and logistics and must always be clear and legible.

The marking systems usually consist of different components that allow them to be used flexibly. Flexibility plays a major role in industrial marking, as the various industrial sectors place very different demands on marking. In the following, we will give you an overview of Texit's industrial marking systems and their possible applications.

Labeling options in the industry

Labeling in the industry is very diverse and includes the labeling of packaging (e.g. product packaging, but also shipping packaging) as well as the labeling of machines, systems and individual components and devices that are used in production.

As the topic of "industrial marking systems" is so extensive, we would like to focus below on the marking of machines, systems and components. What distinguishes industrial marking from conventional labeling are, on the one hand, the high requirements that prevail in the production environment and, on the other, the amount of labeling required.

Industry sets high standards

As a rule, extreme conditions prevail in the production environment that we do not find in our everyday lives. High temperature fluctuations, uneven surfaces, contact with acids and solutions, use under water (possibly salt water), permanent outdoor use (UV rays, moisture, ...) are just a few of these. Depending on the industry, there are also the legal regulations and standards that machine and system labels must comply with.

Labeling at high-performance level

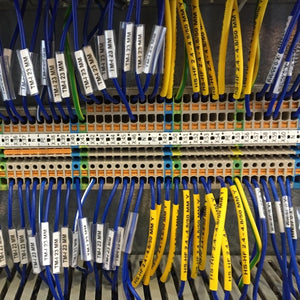

The amount of labeling required also differs from everyday labeling. In manufacturing companies, not only machines, but also individual components and even cables within a system need to be labeled. A suitable marking system must therefore be very flexible to use and be able to produce a large amount of marking in a short time. It should also be easy to use and the marking should be of the highest quality.

Industrial labeling systems from Texit

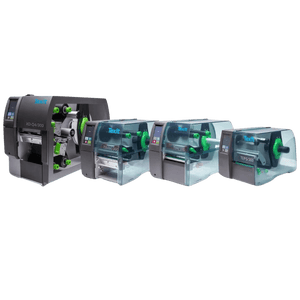

At Texit, we specialized in the industrial marking market 20 years ago. As a manufacturer of industrial labeling, we have designed our products specifically for use in industrial production environments. With our printing systems, you can print cable labels as well as nameplates for components and machines and devices. The systems are perfect for labeling. They are also designed to achieve the highest possible degree of flexibility. You can print on a wide range of different materials and labels with just one thermal transfer printing system.

Komponenten Kennzeichnungssystem

In addition to the material to be printed, such as cable marking or labels, our marking systems consist of a high-performance thermal transfer printer, label software and the appropriate ribbon. The thermal transfer printing process has established itself in industrial labeling systems, as the print result is significantly more consistent and of higher quality than with inkjet printing or laser labeling. In addition, our industrial printers can print at high speed without compromising on print quality.

Thermal transfer printer

Thermal transfer printers are ideal for industrial marking. The printers have a high printing speed and can be used for a wide range of materials (e.g. labeling). The print head melts the ink particles from the thermal transfer foil onto the material to be printed. This produces an extremely robust and permanently legible print result.

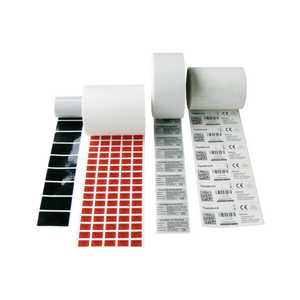

Thermal transfer ribbon

The thermal transfer ribbon is an integral part of our industrial marking systems. The printing ink is transported on it. The foil is inserted into the printer for marking on site. During the printing process, the ink particles are melted onto the material to be printed by the selective application of heat in the print head. This type of ribbon is available in different colors and quality levels and should always be selected to match the material.

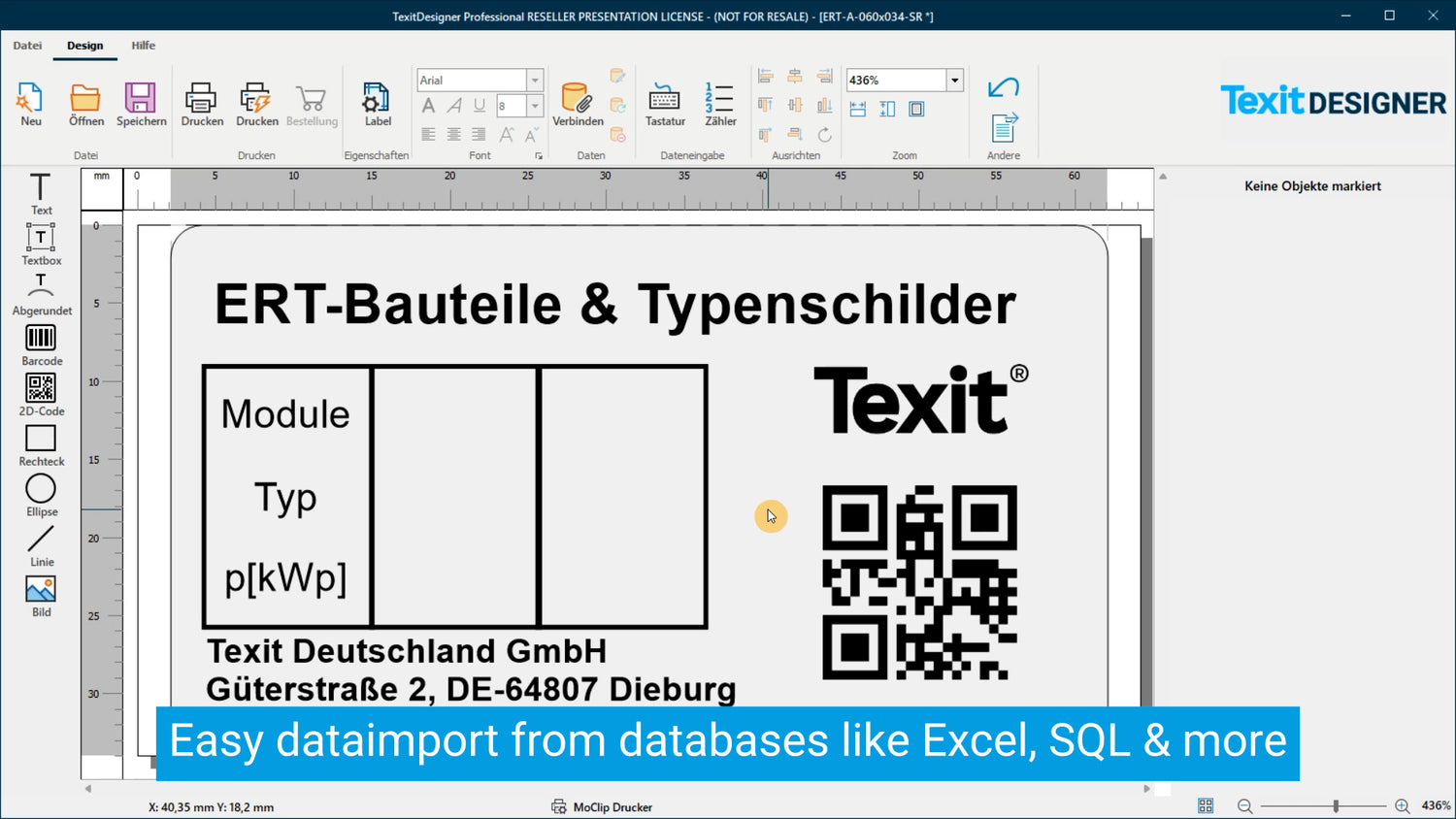

Label software

The label software perfectly rounds off the marking and labeling systems! With the help of the new Texit Designer 11 software, labels and cable marking systems can be designed quickly and easily using drag and drop. In addition to text, you can also easily add barcodes, QR codes, logos or serial numbers (particularly useful for logistics). Thanks to the integrated Excel connection, data transfer is quick and easy. And if any questions do arise, our customers can always get service from our support department. We make labeling easy!

Still have questions about the labeling systems? Simply get in touch with us!

Industrial labeling systems FAQ

Industrial labeling systems are very diverse and complex. We receive questions about our products, solutions and the technology behind them on a daily basis. That's why we've put together some questions and answers for you here. Is your question not listed? Then simply get in touch with us. We will be happy to help you personally. Are you interested in a specific labeling system from us? Then please send us an inquiry. Our labeling experts will take a close look at your situation and work with you to find the optimum solution.

Can the Texit labeling system be used flexibly?

Can the Texit labeling system be used flexibly?

Flexibility is a key feature of an industrial marking system. Our experience shows that industrial sectors have very different requirements for the labeling and marking of machines, systems, devices and components. Our marking systems are therefore very flexible in use in production environments. They can print on different materials and surfaces. In addition, the individual components are compatible with each other and can be exchanged and expanded as required.

In which sectors do industrial labeling systems play a role?

In which sectors do industrial labeling systems play a role?

Marking systems and marking technology play a major role in all sectors and areas of manufacturing companies. This is because all products, packaging, machines and systems must be labeled by law. There is therefore a great need for labeling systems both in manufacturing and in company logistics.

Which materials can be printed on with Texit printers?

Which materials can be printed on with Texit printers?

Texit printers can be used to print on a wide variety of plastics. The use of plastic has become established in the production environment, as it is more robust than paper, but cheaper and more flexible than the use of metals. Plastic markings are also used in the metal industry.

Where can I find more information about the labeling systems?

Where can I find more information about the labeling systems?

You can find more information about our labeling & marking systems under the heading Printing systems. The exact functionality of thermal transfer printers is also explained. If you have any further questions about labeling, you are welcome to contact our labeling experts at any time.

Can the labeling systems be used in a production environment?

Can the labeling systems be used in a production environment?

In the development of our marking systems, use in a production environment was a basic requirement. Marking systems in industry are usually used directly in the production environment.

What labeling solutions are available for industrial product labeling?

What labeling solutions are available for industrial product labeling?

Industrial product marking presents companies with various challenges, including ensuring the precision and legibility of markings, integrating them into existing production processes and adapting them to different materials and outer packaging. Modern marking solutions such as inkjet printers or labeling systems enable flexible and efficient product marking.

One example is the use of sensors that record production data and ensure that the marking is applied in the right place. In-depth expertise is also required to select the right technology for specific requirements and synchronize it with the production processes.