Machine marking is a major component of industrial marking. Reliably functioning and safe machines and systems play an important role for manufacturing companies. In this article, you can find out which elements are included in machine marking and what is important for this type of machine marking.

4 Elements of machine labeling

Machine marking covers a very large and broad field of industrial marking. The sheer number of different machines and systems indicates the diversity of marking. Various regulations, directives, symbols and abbreviations can easily cause confusion. The marking of machines can generally be divided into four areas: Type plates, safety signs, warning signs and maintenance plates. Depending on the industrial sector, there are different machine guidelines and specifications regarding the nature of machine labels. However, the four areas also have something in common: they ensure the reliable and long-term functionality of the machines and the safe handling of such a machine. To achieve this, all elements of the machine marking must be permanently legible and also withstand high loads in the production environment.

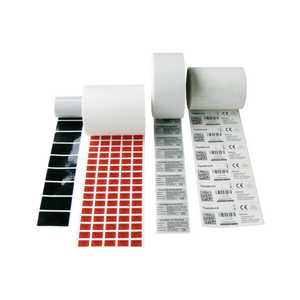

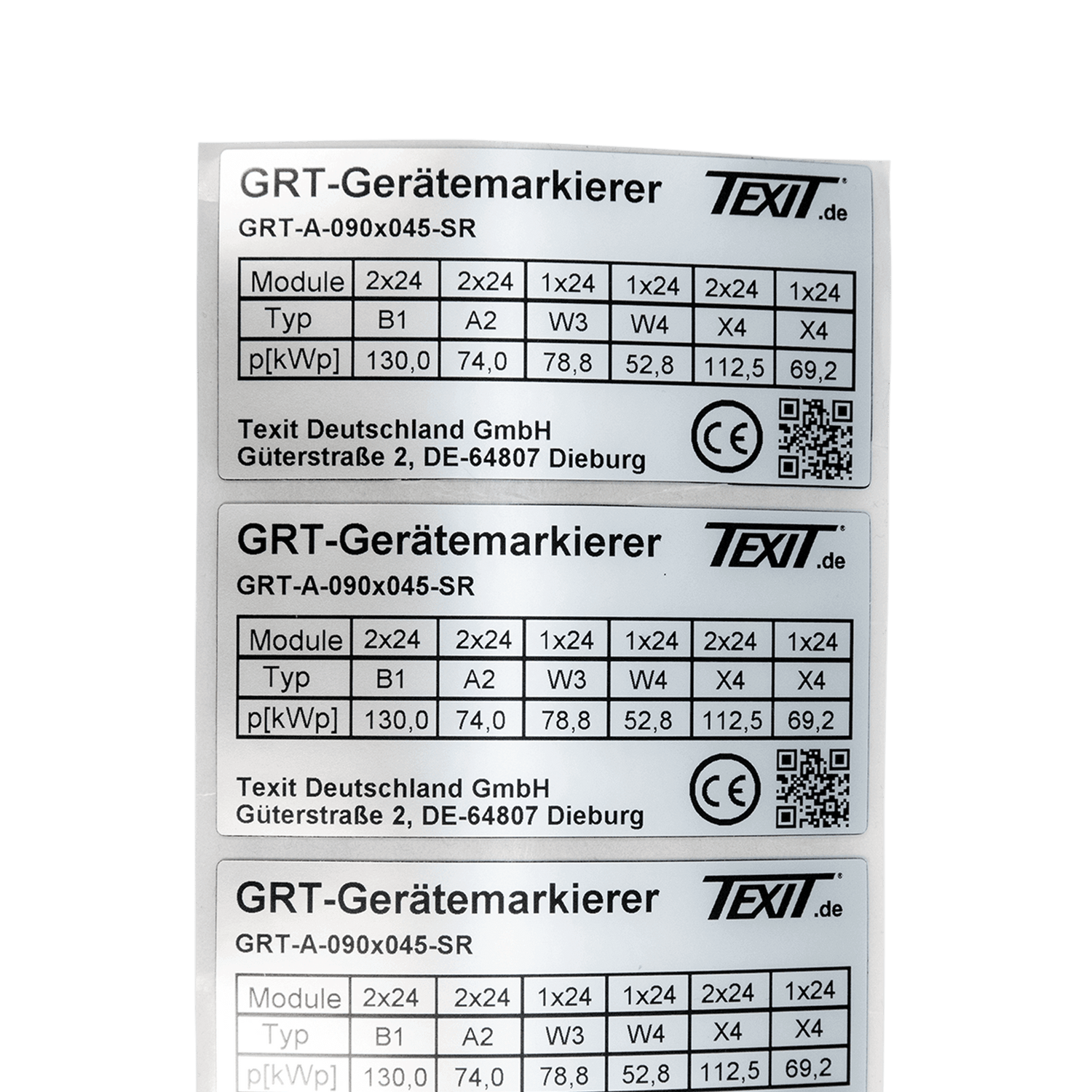

Nameplates for machines

Type plates with CE marking are usually the first association that many people have with machine marking. Type plates are machine plates or machine stickers that the manufacturer affixes when the machine is manufactured. A nameplate usually contains information about the manufacturer (address and company name) as well as information about the machine (CE marking, serial number, year of manufacture, etc.). In addition to the classic, embossed type plates made of aluminum, the more flexible and cost-effective, printable type plates made of plastic have become increasingly popular in recent years. With Texit nameplate labels, you as a machine manufacturer can label your nameplates flexibly and independently with just one printing system.

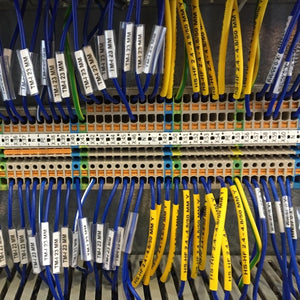

Safety signs for operating the machines

Safety signs are used to ensure safety when using and operating the machines. This category also includes mandatory and prohibition signs, as well as information signs. Text and pictograms are often used on these signs (including arrows indicating the direction of rotation or instructions to protect employees when operating the machine). Robust and permanently legible polyester labels are particularly suitable for this type of machine signage. They are inexpensive to purchase, available in many shapes and sizes and can be printed easily and flexibly with the right thermal transfer printing system. They are also highly resilient and resistant to high temperatures, water, oils and cleaning agents.

Warning signs for safe work processes

Similar to safety signs, warning signs on machines also ensure the protection of employees and safe use. Unlike safety signs, warning signs are usually signal yellow in color and warn people of risks and dangers when operating machines. There are legal requirements and standards for the use of warning signs, which must be complied with depending on the machine. Warning signs always contain a reference to potential sources of danger and the associated risks and are intended to prevent accidents during operation. This is why, strictly speaking, warning signs also belong to the safety marking categories for machine markings. You can design the self-adhesive warning signs from our range yourself on site according to your specifications using the appropriate thermal transfer printing system and print them so that they are permanently legible.

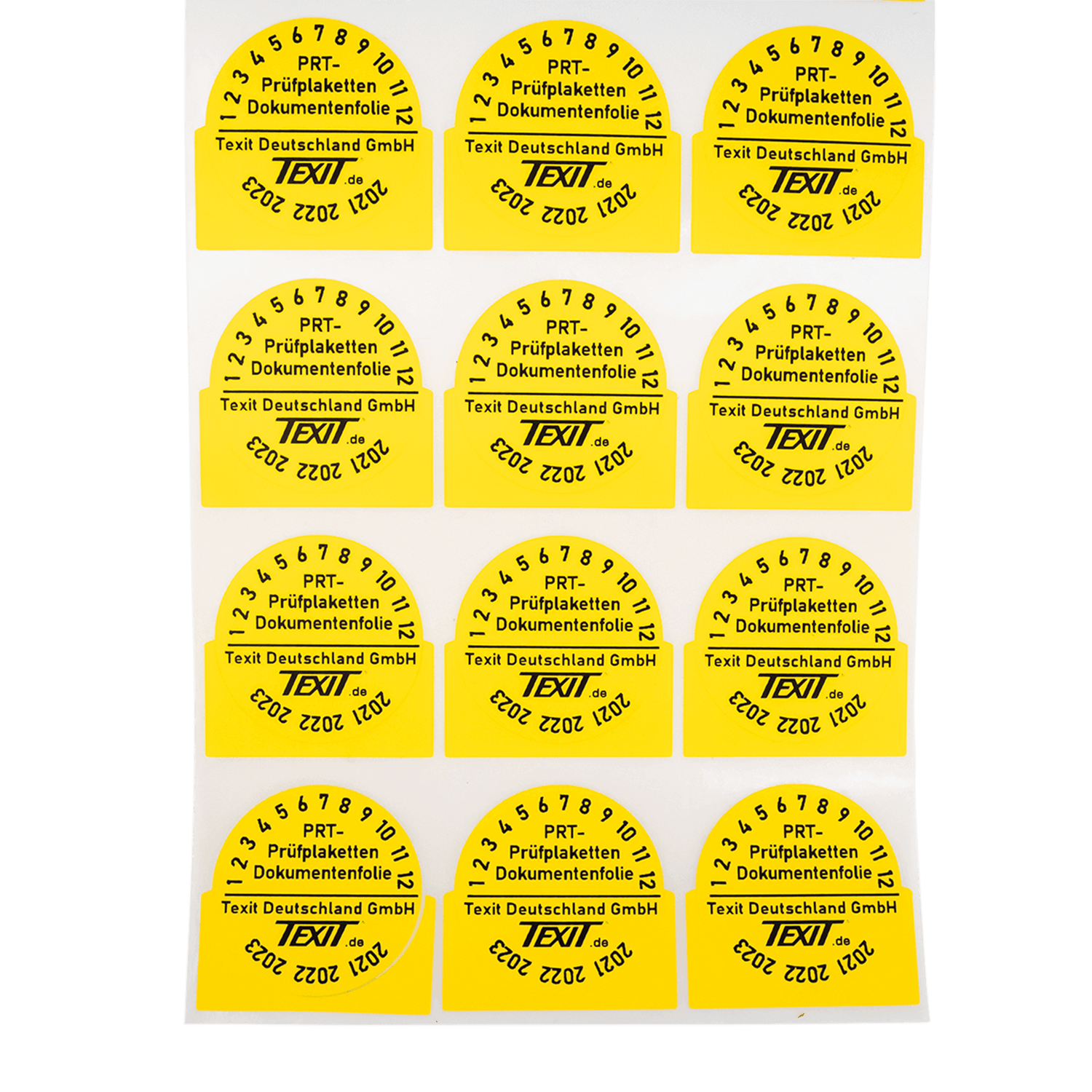

Maintenance stickers as machine plates

Devices as well as machines and systems must be serviced regularly to ensure long-term safe use. Machine signs in the form of inspection labels and maintenance stickers are used here as part of the safety labeling. A machine sign of this type ensures that maintenance is adhered to in production. Instead of pictograms and symbols, maintenance stickers contain the date for the next maintenance. The quality of the inspection stickers depends on the materials used and the printing system. Depending on the specifications, legal standards and requirements, either stickers made of vinyl or tamper-proof document film are used. Both materials are individually designed. You can print the badges flexibly on site using the appropriate printing system.

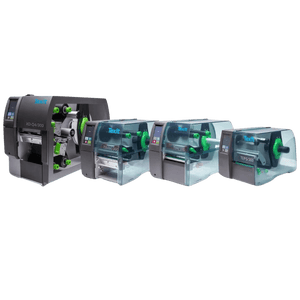

Flexible self-printing of machine labeling

As machine labeling is very extensive and individual, flexible on-site printing offers an efficient and cost-effective way of producing labels for machines of all kinds. A wide variety of signs and stickers for machines can be created and printed with just one printing system. The self-adhesive machine signs then simply need to be attached to the relevant machine parts or devices. As a manufacturing company, you can cover many requirements (regarding safety, machinery directive & standard) at the same time with just one system and benefit from maximum flexibility when designing the labeling of your machines.

Finally, we have compiled an overview of the most frequently asked questions and answers. Do you need help choosing the right machine marking? Then simply get in touch with our service department - our labeling experts will provide you with individual and completely non-binding advice. Together we will find the right marking system for your machines, devices and systems.

Machine marking FAQ

Which stickers to use for machine labeling?

Which stickers to use for machine labeling?

Durable plastic stickers are particularly suitable for machine labeling. Polyester, for example, is cost-effective and highly durable thanks to its special coating. Plastic labels can be printed in high quality and permanently legible using a thermal transfer printer. Depending on your individual requirements (machinery directive, safety ISO standards, etc.), we will be happy to provide you with suitable products and printing systems. Most of our products can be tested in advance as free samples at your premises.

Machine identification signs: What is suitable?

Machine identification signs: What is suitable?

Both vinyl and polystyrene signs are suitable as machine signs. These are available in various shapes and colors and are extremely durable, but also inexpensive to purchase. With the right thermal transfer printing system, you can design and then print the lettering on the signs flexibly on site. This not only saves time and money during production, but also time and stress during periodic maintenance.

How long is the delivery time for machine marking?

How long is the delivery time for machine marking?

The delivery time for all products from our standard range is usually 3-5 working days. As we have our own production facilities and a large warehouse, we usually have our standard products in stock and can ship them directly.

However, custom-made products are also frequently in demand in industry. Custom-made products play a particularly important role in machine marking. Thanks to our production facility within Europe, we can also guarantee fast deliveries for products made especially for you. Of course, the delivery time for such items is longer than the usual 3-5 working days. You can find the exact details in your order confirmation.