Printing your own inspection badges can be a practical and cost-effective solution for industrial companies. With a suitable printing system and appropriate software, badges can be designed quickly and flexibly. However, it is important that the print quality is high and that the badges meet the legal requirements. At Texit, this is exactly what we specialize in and we have a lot of experience in printing inspection labels. In this article, we will show you how you can print your own inspection stickers quickly and easily in 3 steps.

Step 1: Material and printing system selection

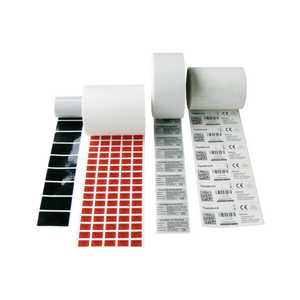

To be able to print permanently legible inspection tags yourself, you need inspection tags and a suitable printing system. First of all, you should determine the right labels for your requirements: Do you need tamper-proof inspection tags made of document film or should the inspection tags be as inexpensive as possible? Then inspection tags made of vinyl/PVC film are also very suitable. Both materials are already provided with adhesive (acrylate adhesive) and are self-adhesive. Which printing system you then need depends on the material selected. The thermal transfer printing process guarantees the highest quality printing results and can be used flexibly. For printing test labels, we recommend using our TEP label thermal transfer printer. This printer model is small and handy and perfectly suited as a test label printer.

-

Vinyl puddle badges

Vinyl inspection badges are inexpensive, self-adhesive and very robust. This variant is often completely sufficient.

-

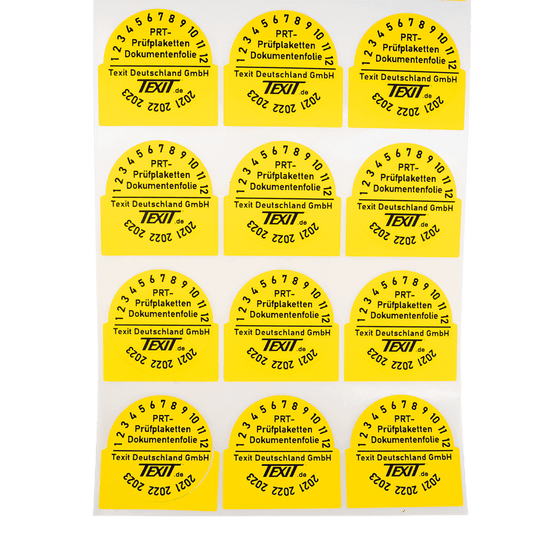

Tamper-proof inspection stickers

Inspection stickers made of document foil are tamper-proof and cannot be falsified once they have been affixed.

-

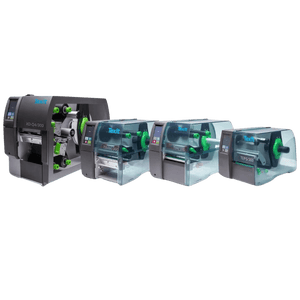

Test badge printer

With our TEP 5 thermal transfer printer labels, the inspection stickers are easy to print.

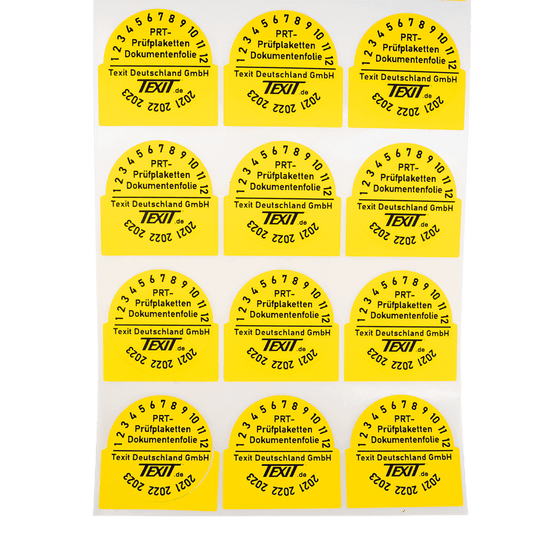

Step 2: Designing the inspection stickers

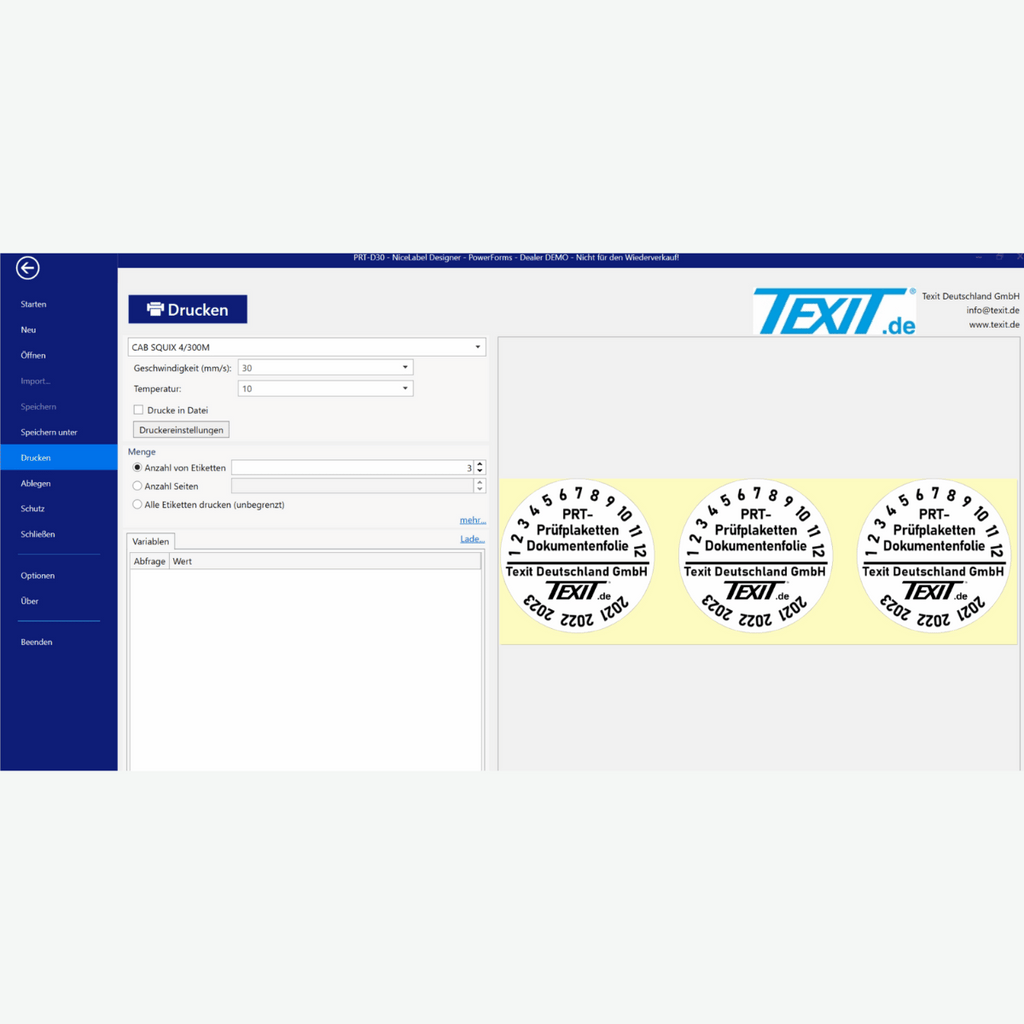

Once you have selected the right material and printer, it's time to design the inspection stickers. One of the biggest advantages of "print your own stickers" is that you can design truly individualized inspection stickers. We have developed our Texit Designer 11 software for the design. This label design software is very user-friendly and easy to use. You can find the exact template (size, format and diameter) of your Texit inspection sticker simply by entering the article number and then drag and drop the desired elements (e.g. text, logo, inspection seal, data on the inspection date or standard) onto the inspection stickers. You can design the labels according to your requirements with your desired text, company logo, QR codes, information on the inspection date & inspection obligation and much more.

Here you can discover our new design software interactively with all its functions!

Step 3: Printing the test labels

Once you have designed the inspection stickers yourself, you can print them. All you need to do is connect the computer to your thermal transfer label printer , specify the desired number of inspection badges and start the printing process. For the first print, we recommend entering a small number first and checking the device and the print results. Do the results meet your requirements? Then you can now print the desired number of test labels. You can also easily adapt the templates created in the software at any time and print different test labels for tests. Thanks to the high-quality thermal transfer printing process, the print results are extremely robust and resistant to oil, petrol, water (& moisture), UV radiation and cleaning agents.

Advantages of printing your own test labels

There are many reasons to print your own inspection stickers. In terms of quality and properties, self-printed inspection stickers are in no way inferior to pre-printed stickers - provided you use the right thermal transfer printing system (matched to the sticker material). We have summarized the biggest advantages for you:

- Time saving: If you print the inspection stickers yourself, you save time and money. You don't need a printing service and don't have to wait for orders.

- Flexibility: By printing your own inspection labels, you can respond more flexibly to individual requirements and use one and the same printing system to print different labels.

- Cost savings: Printing your own inspection stickers can be more cost-effective than buying pre-printed stickers in large quantities. This is a major advantage, especially in combination with the flexibility aspect.

- Control: When you print the inspection badges yourself, you have full control over the design, size, colors and quality of the badges. No more waiting for delivery and no more complaints.

Do you have any questions about printing inspection stickers? We will be happy to advise you!

FAQ Test badge printer

Which inspection sticker printer do I need?

Which inspection sticker printer do I need?

Which printer is best for you depends primarily on the quantity of inspection stickers you want to print. In general, we do not recommend a laser printer for inspection stickers in industry (inspection stickers for the next inspection date with year and inspection seal for which special regulations apply), but rather a thermal transfer printer. We have various printer models in our range (you can find the printers either by searching for thermal transfer printers or by entering the type no.). You can find more information about the specific printers on the product pages. If you would like to compare the printers, simply add the different models to the shopping cart. You will then receive a quote for comparison and, on request, free advice from our labeling experts! The choice of printer depends not only on the company and the inspector, but also on compliance with the regulations (e.g. DGUV or certain seals for electrical appliances or technical systems or equipment) and the inspection intervals.

Who are Texit inspection stickers suitable for?

Who are Texit inspection stickers suitable for?

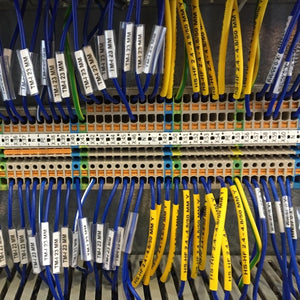

Our Texit test labels (made of tamper-proof document film or inexpensive vinyl film) are suitable for all electrical installation companies, workshops, industrial companies with production facilities, authorities etc. that require regular test labels for their recurring maintenance work. Our test labels are also ideal for mobile service providers who test electrical devices on site at customers' premises (e.g. in accordance with DIN VDE 0701-0702). In our online store, you can easily select the products by quantity. Regardless of whether you need test stickers for the next test date or TÜV stickers for 2025.

In summary, Texit self-printing inspection stickers are suitable for:

- Electrical installation companies (electrical testing)

- Workshops

- Industrial company with own production

- Mechanical engineer

- Facility management company

- Occupational safety specialists or safety technicians

- (mobile) testing service providers

- Public institutions and authorities (hospitals, schools, administrations, ...)

Who is a Texit inspection sticker printer suitable for?

Who is a Texit inspection sticker printer suitable for?

Our Texit test badge printers are particularly suitable for the following companies:

- (Industrial) companies with internal testing organization (equipment testing according to DGUV V3)

- Testing service providers Companies that test electrical devices for their customers (in accordance with DIN VDE 0701-0702)

- Facility management companies that manage large buildings with technical equipment

- Certified specialist companies (e.g. for fire protection in accordance with DIN 14406, shelving systems in accordance with DIN EN 15635 or ladders and steps in accordance with BertSichV)

With a Texit test badge printer, these companies benefit from flexibility, cost savings and simple individualization or documentation when it comes to professional testing of electrical devices / machines / components.

Which materials are suitable for printing inspection stickers?

Which materials are suitable for printing inspection stickers?

There are various materials that can be used for printing inspection stickers. The choice of material depends heavily on your individual requirements. A sticker made of tamper-proof document film is sometimes prescribed - but often the cheaper type made of vinyl or PVC film is also sufficient for the stickers (e.g. for printing TÜV stickers for cars).

What sizes are common for inspection stickers?

What sizes are common for inspection stickers?

Inspection stickers are available in various sizes. The size often depends on the size of the appliance or machine to which the sticker is to be attached. The most common sizes are 15mm & 30mm (diameter). Yellow is usually used as the color, but white is also often used. In our online store you can select the size using the filter.

How long do Texit inspection stickers last?

How long do Texit inspection stickers last?

The durability of our test labels depends on various factors, such as the type of material, the weather conditions and the environment in which the labels are applied. However, they generally last for several years (see customer rating).

Can I print inspection stickers with a logo?

Can I print inspection stickers with a logo?

Yes, an inspection sticker with a logo can be created quickly and easily with the Texit Designer 11 software. You can simply drag and drop the logo for your individual inspection stickers onto the inspection sticker as a graphic. You can find the corresponding inspection sticker templates for company logos using the software's search function: simply enter the article number and get started.