With a nameplate printer, you can flexibly design and produce nameplates for machines, devices and systems yourself in no time at all. And this is possible with a suitable thermal transfer label printer. In this article, we will introduce you to the various printer models from Texit and show you what you need to look out for when making your choice. Printing nameplates has never been so easy.

Advantages of nameplate printers

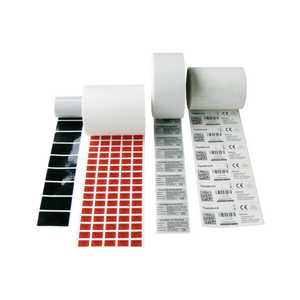

With a nameplate printer, you can create nameplates flexibly yourself and adapt them to current requirements. Flexibility in creation is one of the biggest advantages of nameplate printing. Instead of having to define exact purchase quantities in advance and plan the print in detail, you can adapt all of this at any time according to your wishes and requirements. The nameplates are made of high-quality plastic (polyester) with an integrated foam carrier instead of metal. Thanks to the permanent acrylic adhesive, the nameplate labels adhere securely and label machines, electrical appliances and systems so that they are permanently legible. Another advantage of the labels is the cost saving, with consistent durability and resistance. The blank nameplates are supplied on a practical roll and can therefore be inserted directly into the label printer. After printing, the labels can be attached directly for identification. The type plate printer is very flexible in use. In addition to type plates, you can also use it to print other labels, cable markers or even shrink sleeves (depending on the printer type or printer model). To summarize the most important advantages:

- Maximum flexibility in labeling for manufacturers of machines, systems & devices

- Cost savings compared to conventional metal type plates

- Highly robust rating plate labels (UV radiation & temperature resistant, smudge & abrasion resistant, resistant to water, oil, grease and chemicals)

- Time-saving thanks to simple operation and installation

- Nameplate printer can be used for other labels, cable labeling and heat-shrink tubing

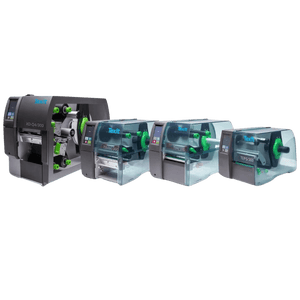

Nameplate printer in comparison

At Texit, we have various rating plate printer models in our range. This means we have a suitable label printer to choose from for every application. Regardless of whether you opt for the standard model (entry-level version) or a high-performance industrial printer: You are guaranteed to benefit from the advantages mentioned above. With all printers, we guarantee printing of the highest quality and reliability, provided the printing system is well matched (ribbon and label materials).

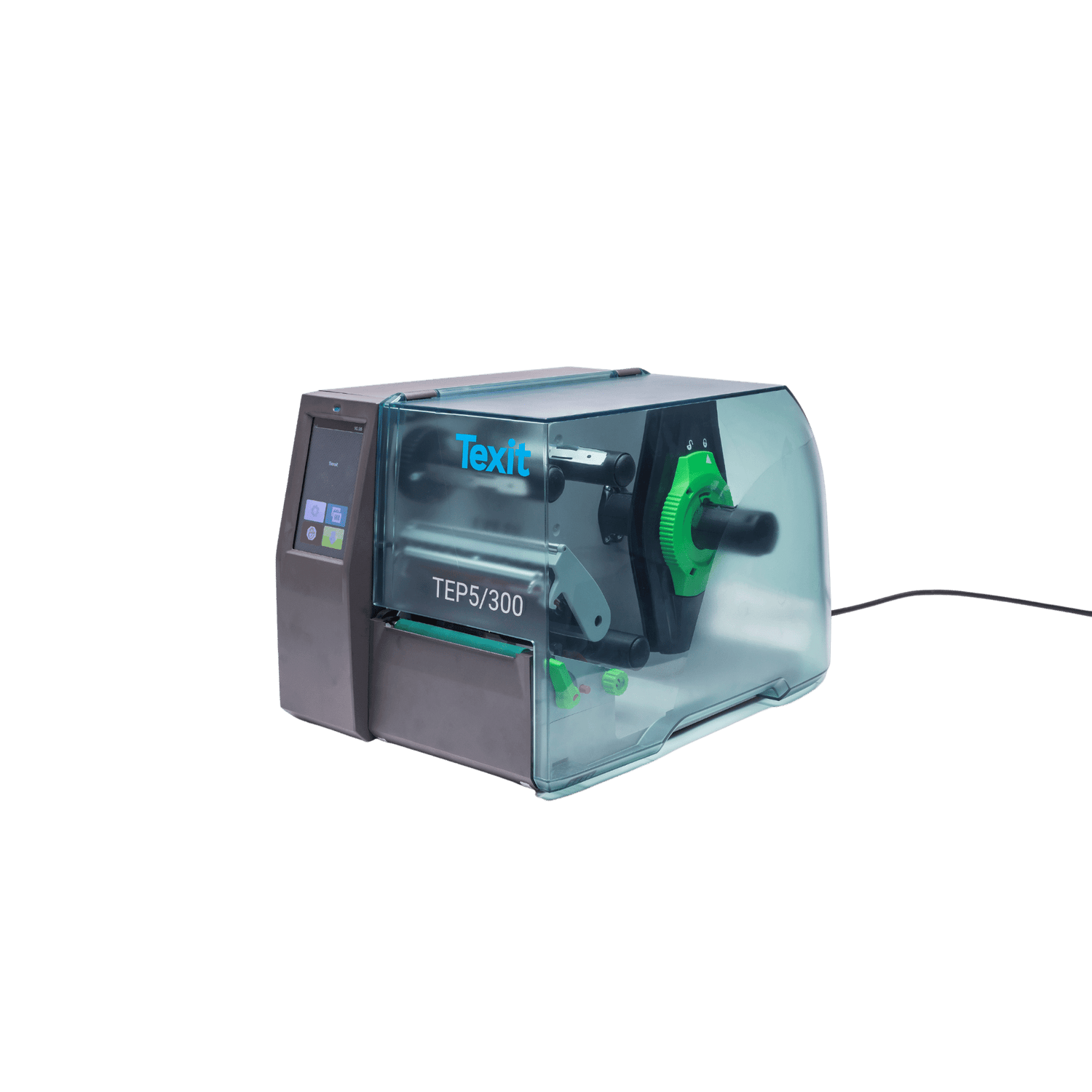

TEP5 Typenschilddrucker Basismodell

We also like to call our TEP5 type plate label printer our entry-level model. This has nothing to do with the print quality, but with the flexibility in industrial use and the printing speed (max. 150 mm/s). The small, handy thermal transfer printer can easily be taken to the construction site or workshop (weight 5 kg) and scores with its high compatibility. It can also print labels and shrink sleeve markers in continuous format without any problems. We recommend the TEP5 printer for occasional nameplate requirements and when the mobility of the printer is important.

TX4 nameplate industrial printer

With the TX4 nameplate printer, you get a high-performance industrial printer that is ideally suited for regular use in industry (also for 24/7 continuous operation). The print speed of up to 300 mm/s enables the implementation of a large print volume. The printer has numerous interfaces and can be upgraded with additional components (e.g. external unwinder, cutter, etc.). Unlike the TEP5 and the TX4M, however, this thermal transfer printer cannot print on continuous material.

TX4M nameplate printer All Around

Our TX4M is also a high-performance printer type for industry. This industrial printer has the same features as the TX4 nameplate printer (in terms of speed, interface, weight, etc.), but with the additional feature that this printer can also print on continuous material. This means that there are no limits to its flexibility. With this type of printer you can also print cable labels (e.g. cable labels) and shrink sleeve markers in addition to rating plates.

Do you need help choosing a type plate printer? We will be happy to advise you!

FAQ Nameplate printer

As we receive many questions about nameplate printers every day, we have compiled the most frequently asked questions and answers for you here. On the thermal transfer printer page you will also find a detailed tabular comparison of the models.

However, please bear in mind that labeling is a very individual area and the answers are not always universally valid, but depend heavily on the regulations and requirements on site. That is why we offer all interested parties free and non-binding advice on our products. Safety at work is important to us. Simply contact us for individual advice. Our labeling experts will be happy to help you. You can also have nameplates made by us.

What are nameplate labels?

What are nameplate labels?

Nameplate labels are nameplates in the form of labels. These labels have the properties of a label (e.g. are equipped with adhesive) and are made of label material (plastic). Just like labels, they can be printed with a label printer (in this case a type plate printer) so that they are permanently legible. However, nameplate labels are special labels with particular advantages. Thanks to the special surface, the lettering is permanently legible. Provided the correct label printing has been used. The appearance of nameplate labels is very similar to that of conventional metal nameplates. However, nameplate labels are significantly cheaper and more flexible in use.

Which printing process is suitable for nameplate labels?

Which printing process is suitable for nameplate labels?

Thermal transfer printing is recommended for printing nameplate labels. With this type of printing, the ink is melted from the thermal transfer foil onto the surface of the rating plate labels by applying heat at certain points. This produces an extremely robust and durable print result. If the correct ribbon is used, the print is smudge and abrasion resistant, as well as resistant to UV light, high temperatures or temperature fluctuations and numerous other environmental influences. Contact with acetone, oils, grease or cleaning agents is also possible without any problems. For this reason, it is particularly important to choose the right thermal transfer ribbon. Depending on the label and material, either a resin-based or wax-based ribbon is generally used.

What printer selection for nameplates is available from Texit?

What printer selection for nameplates is available from Texit?

At Texit we have 4 different types of printers for printing nameplate labels. Which purchase makes sense for you depends in particular on your requirements. All Texit printer types deliver very good printing results for nameplate labels. However, not all printer models are equally flexible in use for different products. We have an inexpensive, small printer (TEP5) as a basic model. For long-term industrial use, we recommend a more powerful printer (TX4). If you also want to print shrink sleeve markers in continuous format in addition to the type plates, you need a printer type that can feed material in the middle (TX4M). And if you also want to print items on both sides, our TD4M double-sided thermal transfer printer is the right model for you.

How long does it take to deliver a nameplate printer?

How long does it take to deliver a nameplate printer?

If we have the printers in stock, the delivery time within Germany is 3-5 working days. There are printer models of which we only have a few in stock (e.g. our TD4M). In this case the delivery time is longer. We will be happy to advise you on the right solution before you buy and also inform you about the delivery time. In some cases, we can also bridge longer delivery times with loan printers. Simply contact our service department. If you need support when setting up the thermal transfer printer, this is of course included in our service.