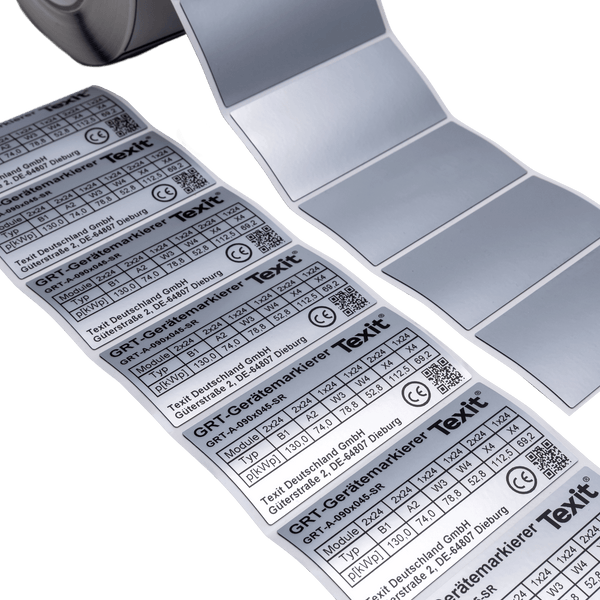

Machine signs

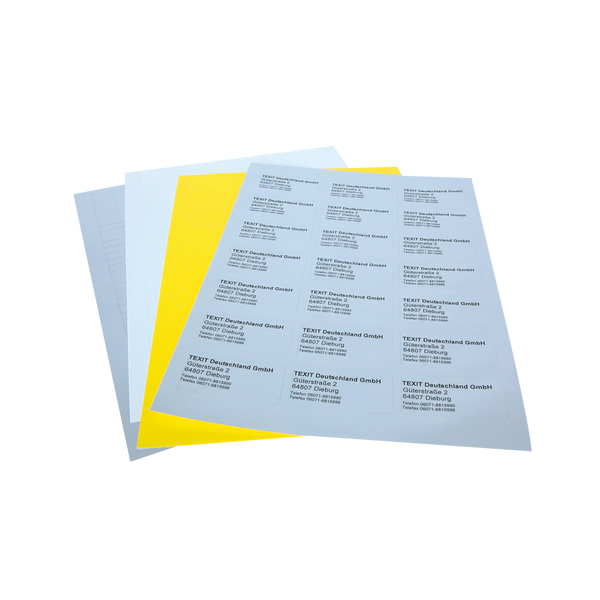

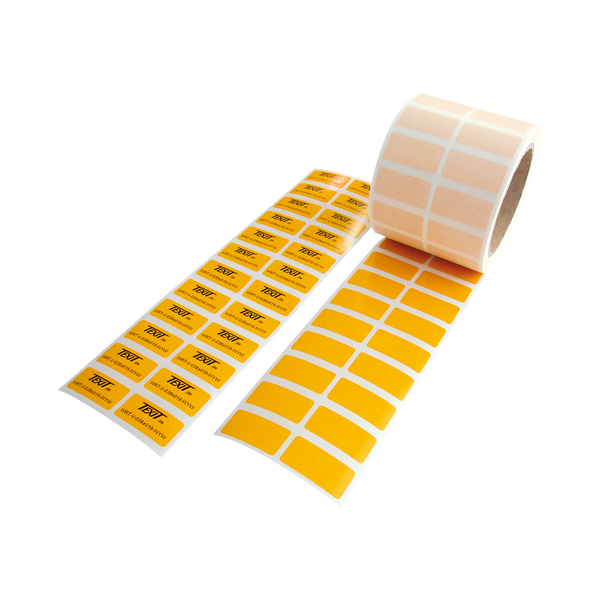

Machine labels are thermal transfer labelswhich are used for marking and labeling machines and systems in industry. While type plates are attached directly by the manufacturer to the new machine in a clearly recognizable manner and contain all important information such as the name of the manufacturer, year of manufacture, CE mark and serial number of the device, machine plates or machine stickers are often used for instructions on safe use. However, both have one thing in common: they are attached to the outside of the machine and the information should be permanently legible even under load and various environmental influences and clearly identify the corresponding device.

And with our new barcode label software, all thermal transfer labels can be designed and printed quickly, easily and flexibly as required. Simply open the appropriate template using the search function and get started.

Discover Texit's range of machine signs here directly online and make your machine marking easy.

Warning signs self-adhesive

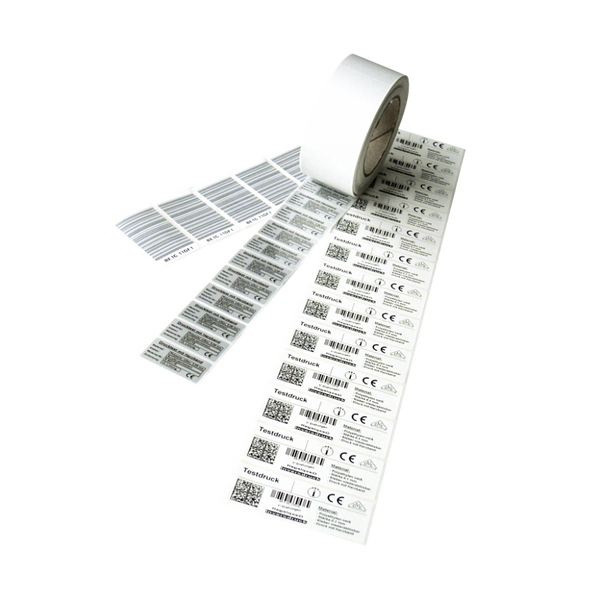

Test labels

Tips for choosing the right industrial labels

Industrial labels come in a wide variety of designs. They differ not only in the type of material used, but also in sizes, colours, adhesive properties, durability and printing method. With the wide range of different labels, choosing the right product is often not easy. However, especially in industry, the labels used should be carefully selected and matched to the specific applications. The following factors play an important role in choosing the right labels:

- Place of use: What do the labels identify? Where is the label placed and what is the nature of the surface there?

- Legal requirements for labels: Are there any specific legal requirements for labelling in the type of use in your industry?

- Physical resistance: What (environmental) influences are the labels exposed to at the place of use?

- Durability: Do the labels need to be changed regularly or should they stick and remain legible for as long as possible?

Based on these general factors, you can already narrow down the product selection considerably. Do you have additional, special requirements for the products? Then don't hesitate to contact our customer support team. Thanks to our many years of experience in the field of industrial labeling, we can provide you with comprehensive advice. Our experts will be happy to help you select the right labels and the right thermal transfer label printer.

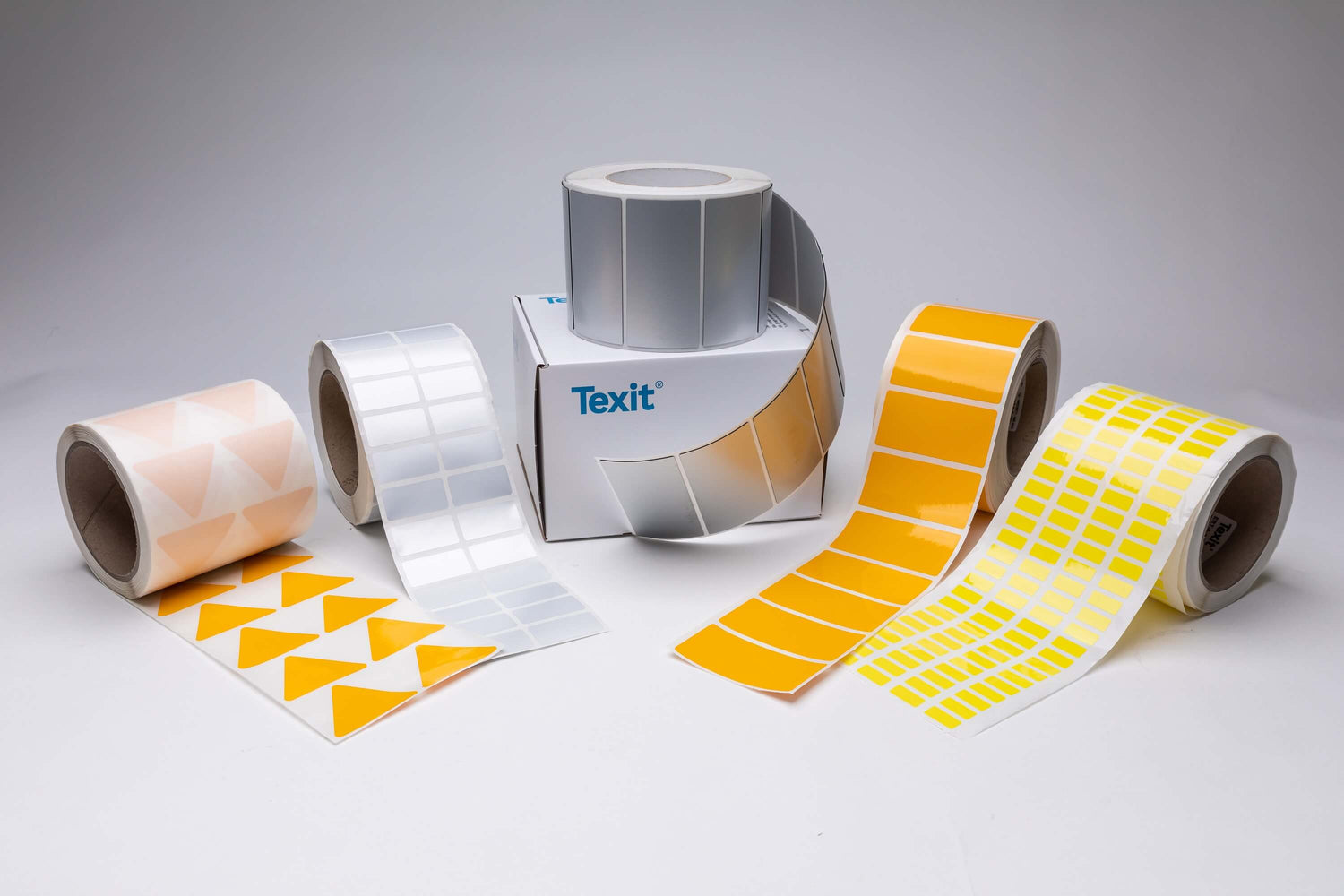

Industrial label material

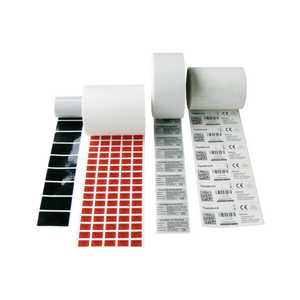

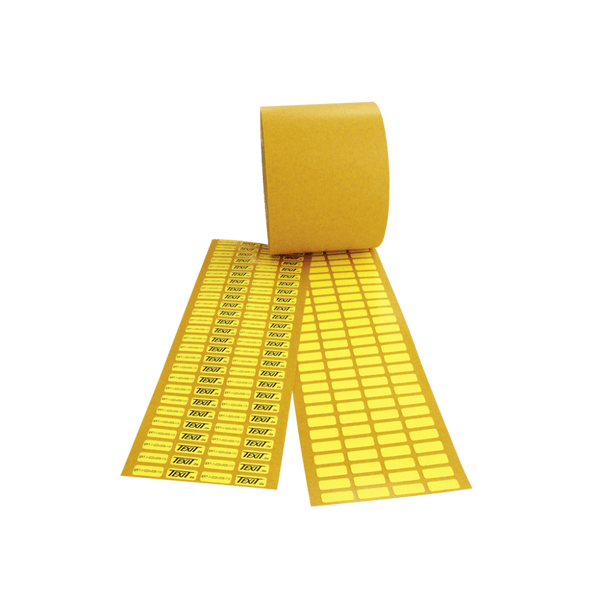

Texit's self-adhesive industrial labels consist of three different materials that are arranged on top of each other like three layers: the backing material, the adhesive and the face material.

The labels are supplied adhesive on the backing material, a type of film. The liner protects the actual labels from contamination and ensures easy peeling and optimal adhesive properties at the time of application. The adhesive is located directly on the liner. The decisive factor for the type of adhesive is its resistance over time. For permanent labelling, we use a permanent acylate adhesive with very strong adhesive properties for our labels. This ensures a long durability of the labels at their place of application. If the industrial label is changed regularly, an adhesive with a lower adhesive strength should be chosen.

The top layer is the label in the true sense of the word. There is a wide range of different materials for the upper material of the labels, especially when used in industry. Since the labels are usually exposed to high physical requirements in manufacturing companies, the use of a plastic is recommended. For the selection of the film, both the condition of the application location (smooth or rough/uneven) and the influences at the location of application are of great importance. At Texit you can choose from products made of the following materials:

Polyester industrial labels

Polyester is one of the most stable materials for the production of plastic cable labels. The labels are therefore durable and can withstand high temperatures. Due to the supple and thin polyester, the labels can be quickly and easily attached to the individual cables. They adhere best to smooth and even surfaces, e.g. metal. Depending on the type of processing, labels made of polyester can either be printed using the thermal transfer process or by means of a laser printer. The latter are particularly suitable for small needs or if the purchase of a thermal transfer printer is not worthwhile.

Vinyl labels

Industrial labels made of vinyl are particularly soft and supple. That is why they are well suited for uneven and rough surfaces. They even adhere reliably to edges and radii. Vinyl labels are free of heavy metals, tear and scratch resistant and temperature resistant. Optimal conditions for use by manufacturing companies. Vinyl, also known as PVC, can be labelled very well using the thermal transfer printing process.

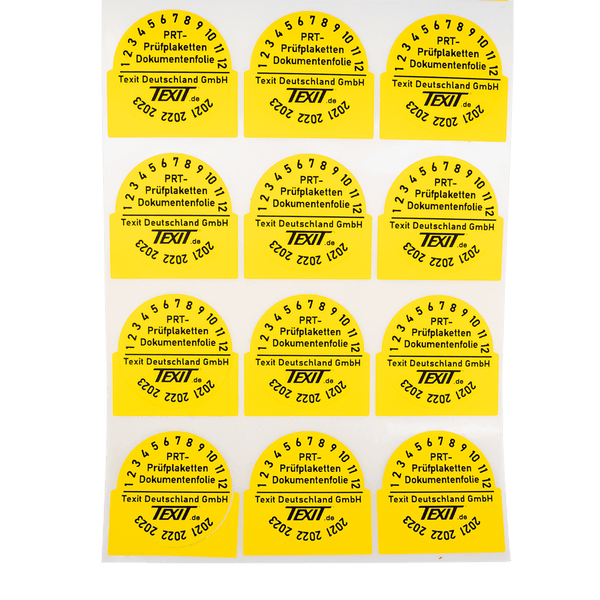

PE Labels from document foil

Our document foil labels are made of polyethylene (also called PE), a plastic that belongs to the thermoplastics. The polyethylene is specially treated as a material so that a tamper-proof film is created. Once applied, it cannot be removed without damage. When pulled off, the PE film tears into small pieces. This is why document film is often used in the production of Inspection labels used. Labels made of PE document film adhere to smooth to slightly rough substrates and are characterised in particular by their resistance to chemicals. Labels made of polyethylene are excellent for thermal transfer printing.

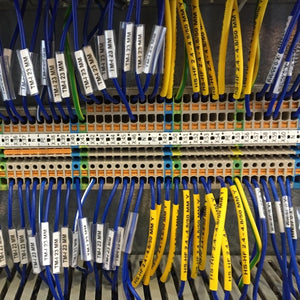

Industrial labels made of textile fabric

At Textile fabric labels the basic material is cotton. This is processed in such a way that it is given special properties. The industrial labels adhere even to the most difficult surfaces, as they are extremely supple thanks to the textile fabric. They are very easy to work with due to the quality of the processing and are often used for equipment labelling and in the control cabinet. These labels can even be used for cable identification. The processed textile material can be individually labelled. Thermal transfer printing achieves the best printing results here.

Print industrial labels yourself or have them printed

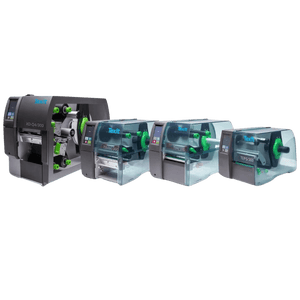

Basically, you can print labels for industry yourself on site or commission the printing from us. In addition, we at Texit also offer you the rental of our thermal transfer printers as a service. This is particularly suitable if you only need the labels for selected projects. However, if you need (different) industrial labels on a long-term and flexible basis, the purchase of your own printing system is recommended. Our Printing systems printers for the thermal transfer printing process are perfectly suited for printing on labels of different materials. The printers guarantee high quality and robust printing results. The maintenance effort of the modern printing systems is very low and takes little time even in the long term. If you have any questions, please contact us. We will be happy to help you. Together we will find the right solution for your requirements!

Industrial labels for the various sectors

Since industry encompasses many different sectors and labels are used everywhere, they have to meet different and often very special and high requirements. On the one hand, the physical conditions vary greatly depending on the place of use. On the other hand, different legal regulations and standards apply in each sector. For example, the regulations in mechanical engineering differ significantly from those in medical or railway engineering. This is why a wide variety of materials are used in the production of industrial labels. Often, special custom-made products must also be produced that have exactly the individually desired properties of the customers.

Thanks to our many years of experience in the field of industrial marking, we have been following the conditions in the various sectors for many years. In recent years in particular, permanent labelling has become more and more specifically defined by standards and guidelines. Therefore, we are also constantly developing our products so that they meet the special legal requirements. On our overview page, you will find more information on the individual sectors and the matching labels. Our experts will also be happy to advise you personally on special requirements. Simply get in touch with us!